|

Note: If you are not at all familiar with basic electronics, you might find it easier to understand this chapter if you read chapter 12 first.

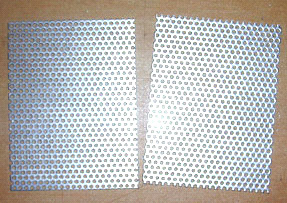

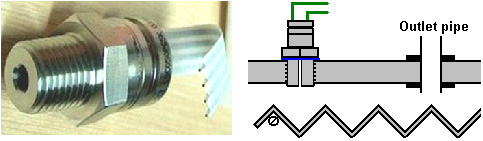

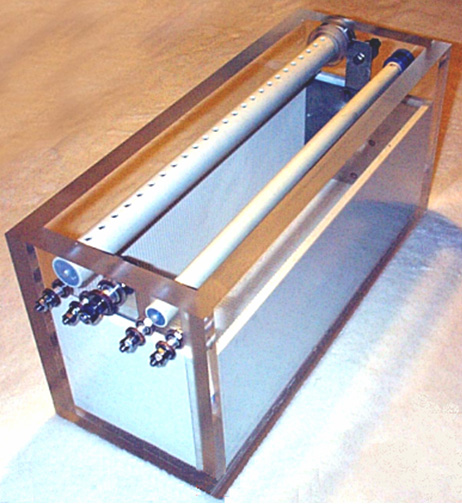

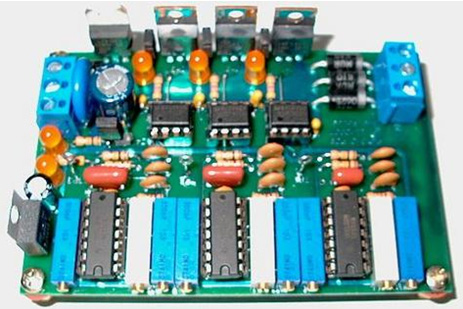

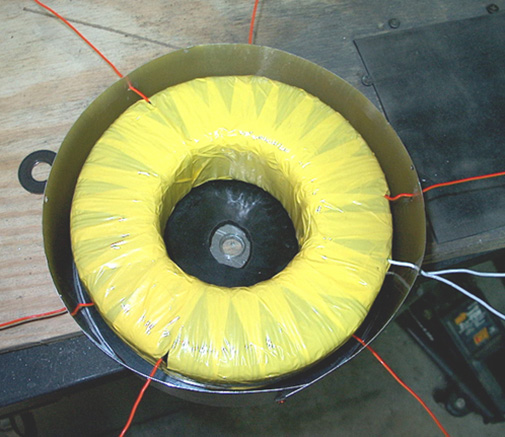

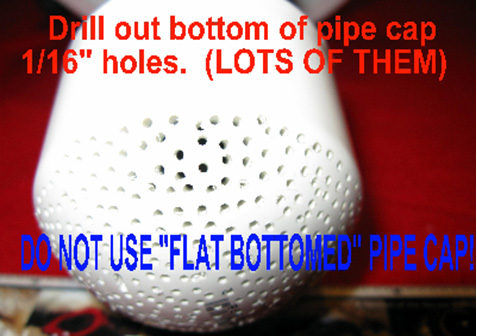

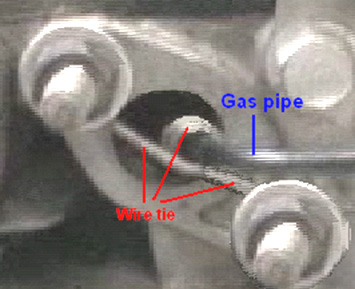

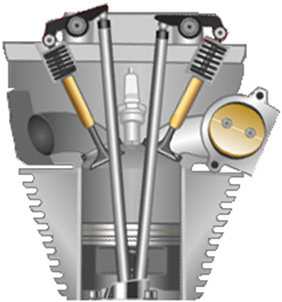

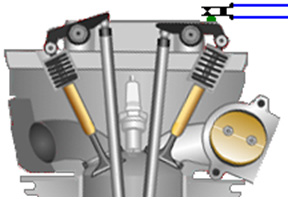

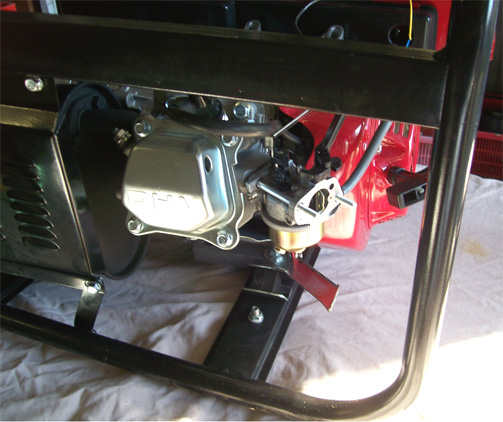

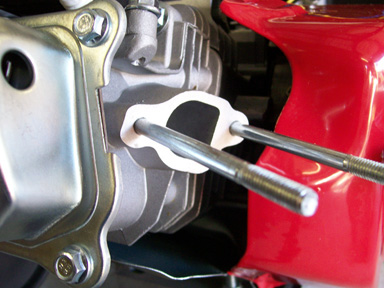

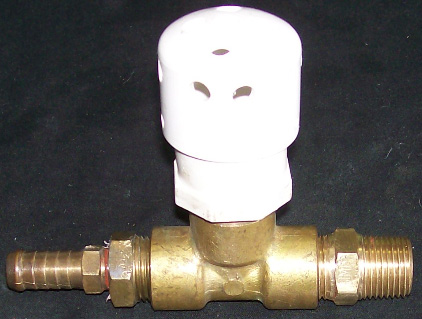

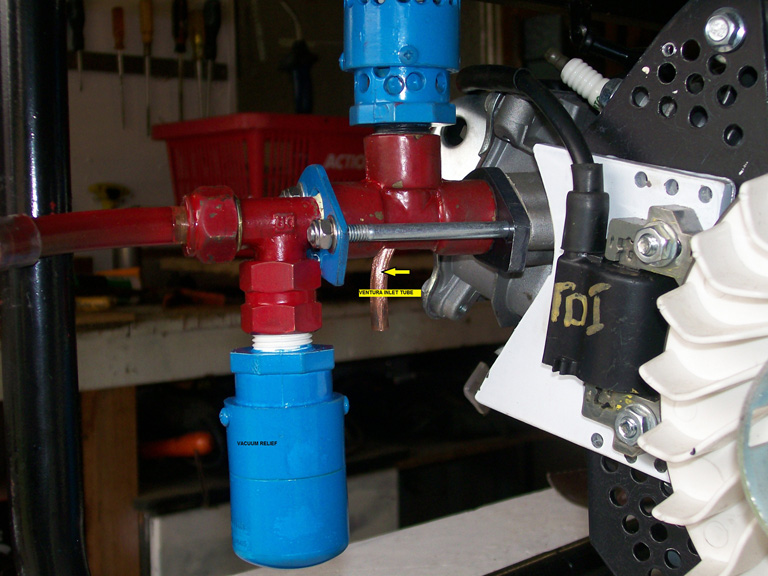

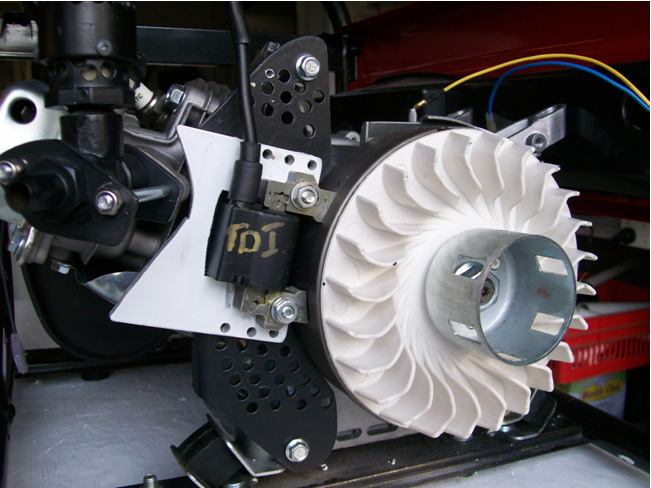

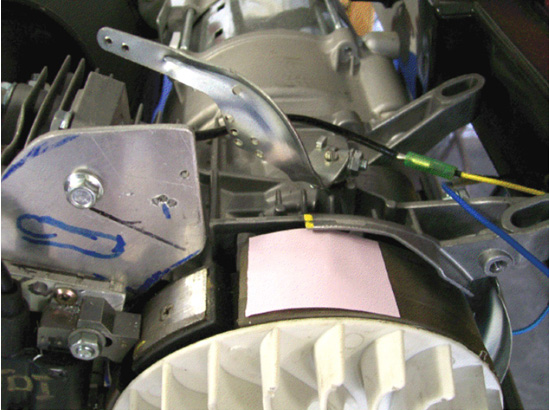

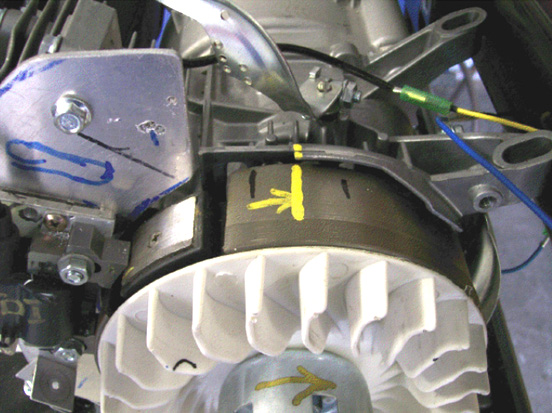

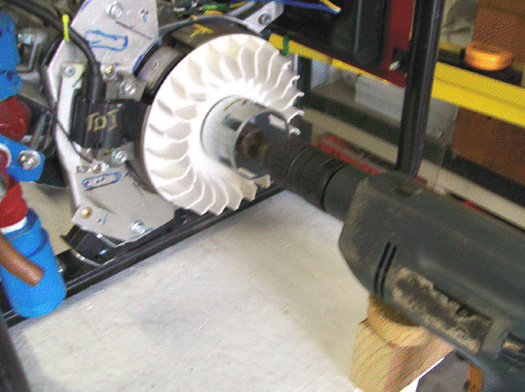

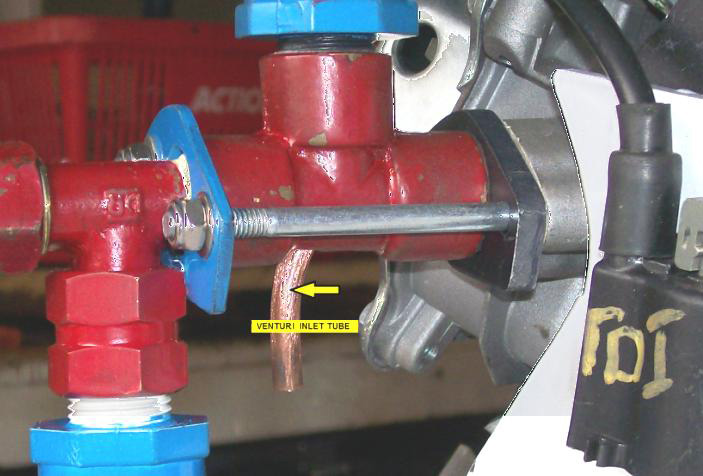

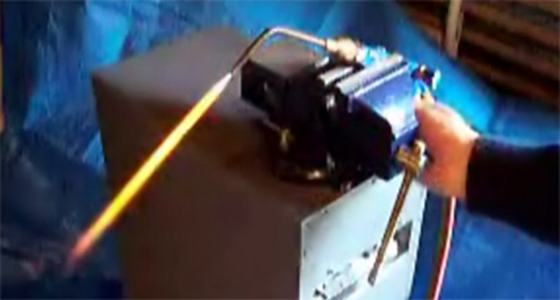

There are two or three main objectives for people who create automotive devices – increasing the mpg performance and reducing the harmful emissions are the top two priorities, while running the vehicle on water alone is the aim of a few people. The first two objectives are readily achievable, but running a vehicle on water alone is not going to happen for almost everybody. This idea is peddled by con artists who sell worthless “plans”, claiming that these will run a vehicle on water for anybody who wants to construct these simple devices. This is just not true. You are welcome to download the "HydroStar" and "HydroGen" plans free from my web site: HydroStar and HydroGen. However, most experienced people looking at these plans are convinced that they could not possibly produce enough hydrogen/oxygen gas mix to run an engine. While I have never heard of anyone, anywhere, ever getting an engine to run on these plans, the present day science of water is so inadequate, that I am not in a position to be certain that they could not work, and so I am just highly doubtful about them being viable devices. Just before getting on to explain the construction details of practical systems, let me put the running of an engine on water alone in its proper context. The internal combustion engine which you own has an efficiency less than 50%. This means that at least half of the energy available from the fuel which you use is wasted and does not produce any useful mechanical output power. In many cases, that percentage can be as high as 90% inefficient, but let’s be generous and assume that your particular engine is especially good and manages 50% efficiency. The main way of running an engine with water as the only fuel, involves splitting water into hydrogen and oxygen and then burning those gases to power the engine. To be self-sustaining, the splitting of the water has to be done by the electrics of the vehicle and that means that the efficiency of the water splitting has to be more than 200% efficient. That just doesn’t happen with simple systems, so please forget the notion of building some device in your garage with a couple of hours work and waving goodbye to filling stations forever – it ain’t going to happen. Just to set the record straight, it is possible to run a vehicle without using fossil fuel, but the difficulty level of doing that is about the same as building a rocket capable of going into orbit, which is something well beyond the capabilities of most people, including me. This document does tell you how it can be done, but please understand that it calls for exceptional skills, very considerable expenditure and a great deal of patience, so for the time being, please forget about it. What can be done quite readily and at low cost, is to construct a device which will raise the efficiency of your engine. This is done by feeding a hydrogen/oxygen gas mix (called “hydroxy” gas) into your engine along with the air which is drawn in to make the engine run. A device of this type is called a “booster” as it boosts the fuel burn, extracting a greater percentage of the fuel’s available energy. An important side effect of this improvement in the burn quality of the fuel is the fact that unburnt fuel no longer gets pushed out of the exhaust as harmful emissions. Another effect is that the engine has greater pulling power and runs smoother. Inside your engine, carbon deposits will have built up from previous un-boosted running. These deposits get burnt away when you use a booster and that extends the engine life. Some people worry about the fact that burning hydroxy gas produces water and they imagine this water causing rusting inside the engine. What they don’t realise is that the ordinary fuel used in the engine is a “hydrocarbon” which is a compound of hydrogen and carbon and that fuel actually splits up to form hydrogen which the engine burns. It is the carbon part of the hydrocarbon fuel which is the problem, producing Carbon dioxide (greenhouse gas), Carbon monoxide, and physical carbon deposits inside the engine. A normal fuel burn produces water anyway, but you don’t get rusting inside the engine as the temperature there is so high that any water is in the form of steam or vapour which dry out completely when the engine is switched off. Adding a small amount of hydroxy gas has no adverse effects at all. This document describes different types of booster. Let me stress that each engine is different and it depends on how inefficient the engine is to begin with, what sort of mpg improvement is likely to be produced by a booster. Just to make sure that you understand what is involved, a booster is a simple container which holds a set of plates submerged in water which probably has an additive to make the water conduct electrical current better. A pipe from the top of the container feeds the gas into the air filter of the vehicle, via one or two simple safety devices. Adding this gas causes a major improvement in the quality of the fuel burn inside the engine and cuts harmful emission to near zero. As a consequence of this, it is possible to reduce the amount of fossil fuel being sent to the engine, which is not something which should be done if hydroxy gas is not being added, as the engine is liable to overheat and some valve damage could occur. It is a completely different matter if hydroxy gas is being added. However, all recent engine designs have an Electronic Control Unit (“ECU”) which controls the amount of fuel being sent to the engine. The ECU accepts input signals from an “oxygen sensor” placed in the exhaust stream, and often a second sensor after the catalytic converter to make sure that the catalytic converter has not failed. Unfortunately, the much improved exhaust caused by the better fuel burn caused by the hydroxy gas, causes the ECU to think that the engine fuel-air mix must be too low, and so it pumps in more fuel in an effort to compensate. Ideally, this can be dealt with by adding a circuit board which adjusts the signal coming from the oxygen sensor so that it is correct for the improved fuel burn. Details of how to do this are in a companion document. So, to recap, the only practical device which you can build yourself and use to improve automotive performance is a ‘booster’. Using a booster improves the efficiency of the fuel burn inside your engine and that results in more power, better torque, smoother running and vastly improved exhaust emissions. If the ECU is not adjusted or its input signal not controlled, the mpg figures may actually get slightly lower due to unwanted excess fuel being pumped into the engine. If a control circuit is used to correct this ECU error, then mpg gains will be produced. So, what mpg gains can be expected? The worst I have ever heard of was 8% which is very rare. The lowest likely gain is 20%. Typical gains are in the 25% to 35% bracket. Not particularly unusual is 35% to 60%, while gains up to 100% and over have been achieved but they are rare. A realistic expectation would be a 33% gain. This chapter is divided up into the following sections: 1. Simple DC boosters, using a 12-volt electrical input. 2. Advanced DC boosters using much higher DC voltages. 3. Water-splitters which use pulsed electrical signals to change water into "hydroxy" gas. 4. Running engines without fossil fuels. 5. Other useful devices. One thing which needs to be understood: Caution: A booster is not a toy. If you make and use one of these, you do so entirely at your own risk. Neither the designer of the booster, the author of this document or the provider of the internet display are in any way liable should you suffer any loss or damage through your own actions. While it is believed to be entirely safe to make and use a properly built booster, provided that the safety instructions shown in this document are followed, it is stressed that the responsibility for doing this is yours and yours alone. 1. Simple DC Boosters It is important that you understand the basic principles of electrolysis if you are to be successful in building and operating a booster, or alternatively, buying and operating a booster. A "DC booster" operates on "Direct Current" which is the sort of electrical power delivered by a car battery. The method is very simple in basic outline. Two metal plates are placed in water and an electric current is passed between the plates. This causes the water to break down into a mixture of hydrogen gas and oxygen gas (The two components used in the Space Shuttle). The greater the flow of current, the larger the volume of gas which will be produced. The arrangement is like this:  Remembering that the result of doing this is to produce fuel for the Space Shuttle, you should avoid doing this indoors and letting the gas produced by the process collect on the ceiling. There are many videos on the web where people act in a dangerous manner and perform electrolysis indoors using a container which is open at the top as shown above. Please, please don't do that as it is highly dangerous - it is not a party popper which pushes the Space Shuttle into space! If you were to collect a cupful of hydroxy gas and light it, the resulting explosion would probably damage your hearing permanently, so don't do it under any circumstances. Just like the fact that a very useful chain saw is a dangerous device which needs to be treated with respect, so too, please understand that the very useful hydroxy gas mix contains a lot of energy and so needs to be treated with respect. This style of electrolysis of water was investigated by the very talented and meticulous experimenter Michael Faraday. He presented his results in a very technical and scientific format which are not understood by most ordinary people. But in simple terms, he tells us that the amount of hydroxy gas produced is proportional to the current flowing through the water, so to increase the rate of gas production, you need to increase the current flow. Also, he found that the optimum voltage between the two "electrode" plates is 1.24 volts. This sounds a bit technical, but it is a highly useful piece of information. In the arrangement shown above, twelve volts is being connected across two plates in water. Faraday tells us that only 1.24 volts of that twelve volts will go to make hydroxy gas and the remaining 10.76 volts will act as an electric kettle and just heat the water, eventually producing steam. As we want to make hydroxy gas and not steam, this is bad news for us. What it does tell us is that if you choose to do it that way, then only 10% of the power taken by the booster actually makes hydroxy gas and a massive 90% is wasted as heat. We really don't want a low electrical efficiency like that. One way around the problem is to use two cells like this:  This arrangement uses our 1.24 volts twice while the twelve volts stays unchanged and so the electrical efficiency goes up to 20% and the heat loss drops to 80%. That is quite an improvement but even more important is the fact that twice as much hydroxy gas is now produced, so we have doubled the electrical efficiency and doubled the gas output, giving a result which is four times better than before. We could go one step further and use three cells like this:  This time we are using three of our 1.24 volt sections and this gives us an electrical efficiency of 30% and three times the amount of gas, making the system nine times more effective. This is definitely going in the right direction, so how far can we take it when using a twelve volt battery? When we use the construction materials which years of testing has shown to be particularly effective, there is a small voltage drop across the metal plates, which means that the very best voltage for each cell is about 2 volts and so with a twelve volt battery, six cells is about the best combination, and that gives us an electrical efficiency of 62% and six times as much gas, which is 37 times better than using a single cell, and the wasted electrical power drops down from 90% to 38%, which is about as good as we can get. Of course, it would not be practical to have six boxes each as large as a car battery as we would never manage to fit them into most vehicles. Perhaps we could just put all the plates inside a single box. Unfortunately, if we do that, a good deal of the electric current would flow around the plates and not make much gas at all. A top view of this arrangement is shown here:  This is a disaster for us as now we will not get your six times the gas production or our massively reduced heating. Thankfully, there is a very simple fix for this problem, and that is to divide the box up into six watertight compartments using thin partitions like this:  This gives us back our high efficiency by blocking the current flow past the plates and forcing the current to flow through the plates, producing gas between every pair of plates. In passing, if this booster were to be powered by the electrics of a vehicle, then the voltage although called "twelve volts" will actually be almost fourteen volts when the engine is running so that the "twelve volt" battery will get charged. This would allow us to use seven cells inside our electrolyser, rather than the six cells shown above and that would give us seven times the gas volume that a single pair of plates would give. Some people prefer six cells, and others, seven cells - the choice is up to the person constructing the unit. We have been discussing the methods of increasing the gas production and reducing the wasted energy, but please don't assume that the objective is to make large volumes of hydroxy gas. It has been found that with many vehicle engines, very good performance gains can be had with a hydroxy gas production rate of less than 1 litre per minute ("lpm"). Flow rates of as little as 0.5 to 0.7 lpm are frequently very effective. Remember, the hydroxy gas from a booster is being used as an igniter for the regular fuel used by the engine and not as an additional fuel. The big advantage of an efficient booster design is that you can produce the wanted volume of gas using a much lower current, and so, a lesser extra load on the engine. Admittedly, there is not much additional engine load needed by a booster, but we should reduce the extra amount by intelligent design. In the discussion above, the battery has been shown connected directly across the booster or "electrolyser". This should never be done as there is no protection against a short-circuit caused by a loose wire or whatever. There should be a fuse or a circuit-breaker as the first thing connected to the battery. Circuit breakers are available from any electrician's supply outlet as they are used in the "fuse box" in homes, to provide protection for each lighting circuit and each power socket circuit. They are not expensive as they are manufactured in very large volumes. They are also available on eBay. The circuit breaker is wired like this:  a common design (rated at 32 amps) looks like this:  Some would-be constructors feel that some aspects of the construction are too difficult for them. Here are some suggestions which might make construction more straightforward. Constructing a seven-cell housing is not difficult. Pieces are cut out for two sides, one base, one lid and six absolutely identical partitions. These partitions must be exactly the same so that there is no tendency for leaks to develop. If you decide to use the bent-plate system of electrodes shown on the next few pages, then drill the bolt holes in the partitions before assembling them:  The bottom piece is the same length as the sides, and it is the width of the partitions plus twice the thickness of the material being used to build the housing. If acrylic plastic is being used for the construction, then the supplier can also provide an “adhesive” which effectively “welds” the pieces together making the different pieces appear to have been made from a single piece. The case would be assembled like this:  Here, the partitions are fixed in place one at a time, and finally, the second side is attached and will mate exactly as the partitions and ends are all exactly the same width. A simple construction for the lid is to glue and screw a strip all the way around the top of the unit and have the lid overlap the sides as shown here:  A gasket, perhaps of flexible PVC, placed between the sides and the lid would assist in making a good seal when the lid is bolted down. The gas outlet pipe is located in the centre of the lid which is a position which is not affected if the unit is tilted when the vehicle is on a steep hill. Years of testing have shown that a really good choice of material for the electrode plates is 316-L grade stainless steel. However, it is very difficult to connect those plates electrically inside the cells as you need to use stainless steel wire to make the connections and bolted connections are really not suitable. That leaves welding the wires to the plates and welding stainless steel is not something which a beginner can do properly as it is much more difficult than welding mild steel. There is a good alternative, and that is to arrange the plate material so that no wire connections are needed:  While this six-cell design may look a little complicated to a quick glance, it is really a very simple construction. Each of the plates used in the central cells is just this shape:  The plate shapes shown above are arranged so that there is access to the bolts from above and they can be reached by a spanner and held steady while the other nut is being tightened. Unless you are skilled in bending plates, I suggest that you use stainless steel mesh for the plates. It works very well, can be readily cut using tin snips or any similar tool and it can be bent into shape by the home constructor using simple tools - a vice, a piece of angle iron, a small piece of mild steel sheet, a hammer, etc. You will find a skip outside any metal fabrication shop where scrap pieces are tossed for recycling. There will be off-cuts of various sizes of angle iron and all sorts of other small sections of sheet and strip. They are in the skip mainly to get rid of them as the fabrication business gets paid almost nothing for them. You can use some of these pieces to shape your booster plates, and if you feel bad about costing the business about a penny, then by all means put them back in the skip afterwards. If you clamp your plate between two angle irons in a vice, then careful, repeated gently tapping with a hammer close to the bend location, will produce a very clean and neat bend in the plate:  The bent sheet can then be clamped between two steel strips and a sharp U-shaped bend produced by tapping with a hammer, again, along the line of the required bend:  The thickness of the steel bar on the inside of the bend has to be the exact width of the required gap between the finished plate faces. This is not particularly difficult to arrange as 3 mm, 3.5 mm, 4 mm, 5 mm and 6 mm are common thicknesses used in steel fabrication, and they can be combined to give almost any required gap. There are many varieties of stainless steel mesh. The style and thickness are not at all critical but you need to choose a type which is reasonably stiff and which will hold its shape well after it is bent. This style might be a good choice:  Your local steel supplier probably has some types on hand and can let you see how flexible a particular variety is. The shape shown above is for a "three plate per cell" design where there are two active plate faces. Ideally, you want two to four square inches of plate area per amp of current flowing through the cell, because that gives very long electrode life and minimum heating due to the plates. This style of construction is reasonably easy to assemble as the two bolts which pass through the partitions and which hold the plates rigidly in place, can be accessed from above, two spanners being used to lock them tight. Lock nuts are optional. If you feel that your particular mesh might be a little too flexible or if you think that the bolts might eventually loosen, then you can attach two, or more, separator insulating pieces - plastic washers, plastic bolts, cable ties or whatever to one of the plate faces. These will hold the plates apart even if they were to become loose. They also help to maintain the gap between the plates. This gap has to be a compromise because the closer the plates are together, the better the gas production but the more difficult it is for the bubbles to break away from the plates and float to the surface and if they don't do that, then they block off some of the plate area and prevent further gas production from that part of the plate as the electrolyte no longer touches the plate there. A popular choice of gap is 1/8 inch which is 3 mm as that is a good compromise spacing. Circular spacers would look like this:  If the current is low enough, an even more simple shape which has just a single pair of active plate surfaces per cell, can be used as shown here:  Any of these designs can be 6-cell or 7-cell and the plates can be constructed without outside help. You will notice that the electrical connections at each end of the booster are submerged to make sure that a loose connection can't cause a spark and ignite the hydroxy gas in the top of the housing. There should be a gasket washer on the inside to prevent any leakage of the electrolyte past the clamping bolt. If you want to use three active plate pairs in each cell, then the plate shape could be like this:  The electrolyte is a mix of water and an additive to allows more current to flow through the liquid. Most of the substances which people think of to use to make an electrolyte are most unsuitable, producing dangerous gasses, damaging the surfaces of the plates and giving uneven electrolysis and currents which are difficult to control. These include salt, battery acid and baking soda and I strongly recommend that you do not use any of these. What is needed is a substance which does not get used up during electrolysis and which does not damage the plates even after years of use. There are two very suitable substances for this: sodium hydroxide, also called "lye" or "caustic soda". In the USA, this is available in Lowes stores, being sold as "Roebic ‘Heavy Duty’ Crystal Drain Opener". The chemical formula for it is NaOH. One other substance which is even better is potassium hydroxide or "caustic potash" (chemical formula KOH) which can be got from soap-making supply shops found on the web. Both NaOH and KOH are very caustic materials and they need to be handled with considerable care.  Bob Boyce of the USA is one of the most experienced people in the construction and use of boosters of different designs. He has kindly shared the following information on how to stay safe when mixing and using these chemicals. He says: These materials are highly caustic and so they need to be handled carefully and kept away from contact with skin, and even more importantly, eyes. If any splashes come in contact with you, it is very important indeed that the affected area be rinsed off immediately with large amounts of running water and if necessary, the use of vinegar which is acidic and so will neutralise the caustic liquid. When making up a solution, you add small amounts of the hydroxide to distilled water held in a container. The container must not be glass as most glass is not high enough quality to be a suitable material in which to mix the electrolyte. The hydroxide itself should always be stored in a sturdy, air-tight container which is clearly labelled "DANGER! - Potassium (or Sodium) Hydroxide". Keep the container in a safe place, where it can’t be reached by children, pets or people who won't take any notice of the label. If your supply of hydroxide is delivered in a strong plastic bag, then once you open the bag, you should transfer all of its contents to sturdy, air-tight, plastic storage containers, which you can open and close without any risk of spilling the contents. Hardware stores sell large plastic buckets with air tight lids that can be used for this purpose. When working with dry hydroxide flakes or granules, wear safety goggles, rubber gloves, a long sleeved shirt, socks and long trousers. Also, don’t wear your favourite clothes when handling hydroxide solution as it is not the best thing to get on clothes. It is also no harm to wear a face mask which covers your mouth and nose. If you are mixing solid hydroxide with water, always add the hydroxide to the water, and not the other way round, and use a plastic container for the mixing, preferably one which has twice the capacity of the finished mixture. The mixing should be done in a well-ventilated area which is not draughty as air currents can blow the dry hydroxide around. When mixing the electrolyte, never use warm water. The water should be cool because the chemical reaction between the water and the hydroxide generates a good deal of heat. If possible, place the mixing container in a larger container filled with cold water, as that will help to keep the temperature down, and if your mixture should “boil over” it will contain the spillage. Add only a small amount of hydroxide at a time, stirring continuously, and if you stop stirring for any reason, put the lids back on all containers. If, in spite of all precautions, you get some hydroxide solution on your skin, wash it off with plenty of cold running water and apply some vinegar to the skin. Vinegar is acidic, and will help balance out the alkalinity of the hydroxide. You can use lemon juice if you don't have vinegar to hand - but it is always a good idea to have a bottle of vinegar handy. The concentration of the electrolyte is a very important factor. Generally speaking, the more concentrated the electrolyte, the greater the current and the larger the volume of hydroxy gas produced. However, there are three major factors to consider: 1. The resistance to current flow through the metal electrode plates. 2. The resistance to current flow between the metal plates and the electrolyte. 3. The resistance to current flow through the electrolyte itself. 1. In a good electrolyser design like those shown above, the design itself is about as good as a DC booster can get, but understanding each of these areas of power loss is important for the best possible performance. We were taught in school that metals conduct electricity, but what was probably not mentioned was the fact that some metals such as stainless steel are quite poor conductors of electricity and that is why electrical cables are made with copper wires and not steel wires. This is how the current flow occurs with our electrolyser plates:  The fact that we have folds and bends in our plates has no significant effect on the current flow. Resistance to current flow through the metal electrode plates is something which can’t be overcome easily and economically, and so has to be accepted as an overhead. Generally speaking, the heating from this source is low and not a matter of major concern, but we provide a large amount of plate area to reduce this component of power loss as much as is practical. 2. Resistance to flow between the electrode and the electrolyte is an entirely different matter, and major improvements can be made in this area. After extensive testing, Bob Boyce discovered that a very considerable improvement can be made if a catalytic layer is developed on the active plate surface. Details of how this can be done are given later in the companion document "D9.pdf" as part of the description of Bob’s electrolyser.  3. Resistance to flow through the electrolyte itself can be minimised by using the best catalyst at its optimum concentration. When using sodium hydroxide, the optimum concentration is 20% by weight. As 1 cc of water weighs one gram, one litre of water weighs one kilogram. But, if 20% (200 grams) of this kilogram is to be made up of sodium hydroxide, then the remaining water can only weigh 800 grams and so will be only 800 cc in volume. So, to make up a 20% "by weight" mix of sodium hydroxide and distilled water, the 200 grams of sodium hydroxide are added (very slowly and carefully, as explained above by Bob) to just 800 cc of cool distilled water and the volume of electrolyte produced will be about 800 cc. When potassium hydroxide is being used, the optimum concentration is 28% by weight and so, 280 grams of potassium hydroxide are added (very slowly and carefully, as explained above by Bob) to just 720 cc of cold distilled water. Both of these electrolytes have a freezing point well below that of water and this can be a very useful feature for people who live in places which have very cold winters. Another factor which affects current flow through the electrolyte is the distance which the current has to flow through the electrolyte - the greater the distance, the greater the resistance. Reducing the gap between the plates to a minimum improves the efficiency. However, practical factors come into play here as bubbles need sufficient space to escape between the plates, and a good working compromise is a spacing of 3 mm. which is one eighth of an inch.  However, there is a problem with using the optimum concentration of electrolyte and that is the current flow caused by the greatly improved electrolyte is likely to be far more than we want. To deal with this we can use an electronic circuit called a "Pulse-Width Modulator" (or “PWM”) circuit. These are often sold as "DC Motor Speed Controllers" and if you buy one, then pick one which can handle 30 amps of current. A PWM circuit operates in a very simple way. It switches the current to the electrolyser On and Off many times every second. The current is controlled by how long (in any one second) the current is On, compared to how long it is Off. For example, if the On time is twice as long as the Off time (66%), then the average current flow will be much greater than if the On time were only half as long as the Off time(33%). When using a PWM controller, it is normal to place its control knob on or near the dashboard and to mount a simple low-cost ammeter beside it so that the driver can raise or lower the current flow as is considered necessary. The arrangement is like this:  There is a more sophisticated circuit controller called a "Constant-current Circuit" and that allows you to select the current you want and the circuit then holds the current at your set value at all times. However, this type of circuit is not readily available for sale although some outlets are preparing to offer them. Some of the most simple boosters don't use a PWM circuit because they control the current flow through the booster by making the concentration of the electrolyte very low so that the resistance to current flow through the electrolyte chokes off the current and holds it down to the desired level. This, of course, is far less efficient and the resistance in the electrolyte causes heating, which in turn, is an operational problem which needs careful handling by the user. The advantage is that the system appears to be more simple. Feeding the hydroxy gas to the engine. When using a booster of any design you need to realise that hydroxy gas is highly explosive. If it wasn’t, it would not be able to do it’s job of improving the explosions inside your engine. Hydroxy gas needs to be treated with respect and caution. It is important to make sure that it goes into the engine and nowhere else. It is also important that it gets ignited inside the engine and nowhere else. To make these things happen, a number of common-sense steps need to be taken. Firstly, the booster must not make hydroxy gas when the engine is not running. The best way to arrange this is to switch off the current going to the booster when the engine is not running. It is not sufficient to just have a manually-operated On/Off switch as it is almost certain that switching off will be forgotten one day. Instead, the electrical supply to the booster is routed through the ignition switch of the vehicle. That way, when the engine is turned off and the ignition key removed, it is certain that the booster is turned off as well. So as not to put too much current load on the ignition switch, and to allow for the possibility of the ignition switch being on when the engine is not running, instead of wiring the booster directly to the switch, it is better to wire a standard automotive relay across the oil pressure unit and let the relay carry the booster current. The oil pressure drops when the engine stops running, and so this will also power down the booster. An extra safety feature is to allow for the (very unlikely) possibility of an electrical short-circuit occurring in the booster or its wiring. This is done by putting a fuse or contact-breaker between the battery and the new circuitry as shown in this diagram:  If you choose to use a contact-breaker, then a light-emitting diode (“LED”) with a current limiting resistor of say, 680 ohms in series with it, can be wired directly across the contacts of the circuit breaker. The LED can be mounted on the dashboard. As the contacts are normally closed, they short-circuit the LED and so no light shows. If the circuit-breaker is tripped, then the LED will light up to show that the circuit-breaker has operated. The current through the LED is so low that the electrolyser is effectively switched off when the contact breaker opens. This is not a necessary feature, merely an optional extra:  A good source for general components needed in building boosters is The Hydrogen Garage in the USA, website. A very important safety item for any booster is the “bubbler” which is just a simple container with some water in it. The bubbler has the gas coming in at the bottom and bubbling up through the water. The gas collects above the water surface and is then drawn into the engine through an outlet pipe above the water surface. To prevent water being drawn into the booster when the booster is off for any length of time and the pressure inside it reduces, a one-way valve is placed in the pipe between the booster and the bubbler. If the engine happens to backfire, then the bubbler blocks the flame from passing back through the pipe and igniting the gas being produced in the booster. A bubbler is a very simple, very cheap and very sensible thing to install. It also removes any traces of electrolyte fumes from the gas before it is drawn into the engine. In practice, it is a very good idea to have two bubblers, one close to the booster and one close to the engine. The second bubbler makes sure that every last trace of electrolyte fumes are washed out of the hydroxy gas before it enters the engine. There are various ways to make a good bubbler. In general, you are aimed at having a five-inch (125 mm) depth of water through which the hydroxy gas must pass before it leaves the bubbler. It is recommended that a bubbler is built inside a strong container such as this one:  These strong containers are generally sold as water filters. They can be adapted to become bubblers without any major work being done on them. At this point, we need to consider the mechanism for moving the hydroxy gas out of the booster and into the engine. It is generally a good idea to position the gas take-off pipe in the centre of the lid so that if the booster gets tilted due to the vehicle operating on a sloped surface, then the surface level of the liquid remains unchanged underneath the gas pipe. A common mistake is to use a gas pipe which has a small diameter. If you take a length of plastic pipe of a quarter inch diameter (6 mm) and try blowing through it, you will be surprised at how difficult it is to blow through. There is no need to give your booster that problem, so I suggest that you select a gas pipe of half an inch (12 mm) or so. If in doubt as to how suitable a pipe is, then try blowing through a sample length of it. If you can blow through it without the slightest difficulty, then it is good enough for your booster. One other thing is how to deal with splashes and the spray from bubbles bursting at the surface of the electrolyte. You want some device which will prevent any spray or splashes caused by the vehicle going over a very rough road, from entering the gas pipe and being drawn out of the booster along with the hydroxy gas. Various methods have been used and it is very much a matter of personal choice as to how you decide to deal with the issue. One method is to use a piece of suitable material across the end of the pipe. This is generally called anti-slosh material because of the job which it does. The material needs to let the gas pass freely through it but prevent any liquid getting through it. Plastic pot-scrubbers as a possible material as they have an interlocking mesh of small flat strands. The gas can flow around and through the many strands, but splashes which go in a straight line will hit the strands and drip back into the booster again. Another possible device is one or more baffles which will catch the liquid but let the gas pass freely by:

OR