Appendix

TABLE OF

WIRE SIZES:

The

wire sizes specified for use in some designs are American Wire Gauge so a

comparison table showing the UK ‘Standard Wire Gauge’ (with lengths on a 500

gram reel of enamelled copper wire), and the ‘American Wire Gauge’ is given

here:

|

AWG |

Dia mm |

Area sq. mm |

SWG |

Dia mm |

Area sq. mm |

Max Amps |

Ohms / metre |

Metres Per 500g |

Max Hz |

|

1 |

7.35 |

42.40 |

2 |

7.01 |

38.60 |

119 |

|

|

325 |

|

2 |

6.54 |

33.60 |

3 |

6.40 |

32.18 |

94 |

|

|

410 |

|

3 |

5.88 |

27.15 |

4 |

5.89 |

27.27 |

75 |

|

|

500 |

|

4 |

5.19 |

21.20 |

6 |

4.88 |

18.68 |

60 |

|

|

650 |

|

5 |

4.62 |

16.80 |

7 |

4.47 |

15.70 |

47 |

|

|

810 |

|

6 |

4.11 |

13.30 |

8 |

4.06 |

12.97 |

37 |

|

|

1,100 |

|

7 |

3.67 |

10.60 |

9 |

3.66 |

10.51 |

30 |

|

|

1,300 |

|

8 |

3.26 |

8.35 |

10 |

3.25 |

8.30 |

24 |

|

|

1,650 |

|

9 |

2.91 |

6.62 |

11 |

2.95 |

6.82 |

19 |

|

|

2,050 |

|

10 |

2.59 |

5.27 |

12 |

2.64 |

5.48 |

15 |

0.0042 |

|

2,600 |

|

11 |

2.30 |

4.15 |

13 |

2.34 |

4.29 |

12 |

0.0047 |

|

3,200 |

|

12 |

2.05 |

3.31 |

14 |

2.03 |

3.49 |

9.3 |

0.0053 |

17.5 m |

4,150 |

|

13 |

1.83 |

2.63 |

15 |

1.83 |

2.63 |

7.4 |

0.0068 |

|

5,300 |

|

14 |

1.63 |

2.08 |

16 |

1.63 |

2.08 |

5.9 |

0.0083 |

27 m |

6,700 |

|

15 |

1.45 |

1.65 |

17 |

1.42 |

1.59 |

4.7 |

0.0135 |

|

8,250 |

|

16 |

1.29 |

1.31 |

18 |

1.219 |

1.17 |

3.7 |

0.0148 |

48 m |

11 kHz |

|

17 |

1.15 |

1.04 |

|

|

|

2.9 |

0.0214 |

|

13 kHz |

|

18 |

1.024 |

0.823 |

19 |

1.016 |

0.811 |

2.3 |

0.027 |

|

17 kHz |

|

19 |

0.912 |

0.653 |

20 |

0.914 |

0.657 |

1.8 |

0.026 |

85 m |

21 kHz |

|

20 |

0.812 |

0.519 |

21 |

0.813 |

0.519 |

1.5 |

0.036 |

|

27 kHz |

|

21 |

0.723 |

0.412 |

22 |

0.711 |

0.397 |

1.2 |

0.043 |

140 m |

33 kHz |

|

22 |

0.644 |

0.325 |

23 |

0.610 |

0.292 |

0.92 |

0.056 |

|

42 kHz |

|

23 |

0.573 |

0.259 |

24 |

0.559 |

0.245 |

0.729 |

0.070 |

225 m |

53 kHz |

|

24 |

0.511 |

0.205 |

25 |

0.508 |

0.203 |

0.577 |

0.087 |

|

68 kHz |

|

25 |

0.455 |

0.163 |

26 |

0.457 |

0.164 |

0.457 |

0.105 |

340 m |

85 kHz |

|

26 |

0.405 |

0.128 |

27 |

0.417 |

0.136 |

0.361 |

0.130 |

|

107 kHz |

|

27 |

0.361 |

0.102 |

28 |

0.376 |

0.111 |

0.288 |

0.155 |

500 m |

130 kHz |

|

28 |

0.321 |

0.0804 |

30 |

0.315 |

0.0779 |

0.226 |

0.221 |

700 m |

170 kHz |

|

29 |

0.286 |

0.0646 |

32 |

0.274 |

0.0591 |

0.182 |

0.292 |

950 m |

210 kHz |

|

30 |

0.255 |

0.0503 |

33 |

0.254 |

0.0506 |

0.142 |

0.347 |

1125 m |

270 kHz |

|

31 |

0.226 |

0.0401 |

34 |

0.234 |

0.0428 |

0.113 |

0.402 |

1300 m |

340 kHz |

|

32 |

0.203 |

0.0324 |

36 |

0.193 |

0.0293 |

0.091 |

0.589 |

1900 m |

430 kHz |

|

33 |

0.180 |

0.0255 |

37 |

0.173 |

0.0234 |

0.072 |

0.767 |

2450 m |

540 kHz |

|

34 |

0.160 |

0.0201 |

38 |

0.152 |

0.0182 |

0.056 |

0.945 |

3000 m |

690 kHz |

|

35 |

0.142 |

0.0159 |

39 |

0.132 |

0.0137 |

0.044 |

1.212 |

3700 m |

870 kHz |

HOWARD JOHNSON: PERMANENT MAGNET MOTOR

Patent US 4,151,431

24th April 1979

Inventor: Howard R. Johnson

PERMANENT MAGNET MOTOR

This is a re-worded extract from this Patent. It describes a motor powered solely by permanent magnets and which it is claimed can power an electrical generator.

ABSTRACT

The invention is directed to the method of utilising the unpaired electron spins in ferromagnetic and other materials as a source of magnetic fields for producing power without any electron flow as occurs in normal conductors, and to permanent magnet motors for utilising this method to produce a power source. In the practice of the invention the unpaired electron spins occurring within permanent magnets are utilised to produce a motive power source solely through the superconducting characteristics of a permanent magnet, and the magnetic flux created by the magnets is controlled and concentrated to orientate the magnetic forces generated in such a manner to produce useful continuous work, such as the displacement of a rotor with respect to a stator. The timing and orientation of magnetic forces at the rotor and stator components produced by the permanent magnets is accomplished by the proper geometrical relationship of these components.

BACKGROUND OF THE INVENTION:

Conventional electric motors employ magnetic forces to produce either rotational or linear motion. Electric motors operate on the principal that when a conductor which carries a current is located in a magnetic field, a magnetic force is exerted upon it. Normally, in a conventional electric motor, the rotor, or stator, or both, are so wired that magnetic fields created by electromagnets use attraction, repulsion, or both types of magnetic forces, to impose a force upon the armature causing rotation, or linear displacement of the armature. Conventional electric motors may employ permanent magnets either in the armature or stator components, but to date they require the creation of an electromagnetic field to act upon the permanent magnets. Also, switching gear is needed to control the energising of the electromagnets and the orientation of the magnetic fields producing the motive power.

It is my belief that the full potential of magnetic forces existing in permanent magnets has not been recognised or utilised because of incomplete information and theory with respect to atomic motion occurring within a permanent magnet. It is my belief that a presently unnamed atomic particle is associated with the electron movement of a superconducting electromagnet and the loss-less flow of currents in permanent magnets. The unpaired electron flow is similar in both situations. This small particle is believed to be opposite in charge to an electron and to be located at right angles to the moving electron. This particle must be very small to penetrate all known elements in their various states as well as their known compounds (unless they have unpaired electrons which capture these particles as they endeavour to pass through).

The electrons in ferrous materials differ from those found in most elements in that they are unpaired, and being unpaired they spin around the nucleus in such a way that they respond to magnetic fields as well as creating a magnetic field themselves. If they were paired, their magnetic fields would cancel out. However, being unpaired they create a measurable magnetic field if their spins are orientated in one direction. The spins are at right angles to their magnetic fields.

In niobium superconductors, at a critical state, the magnetic lines of force cease to be at right angles. This change must be due to establishing the required conditions for unpaired electronic spins instead of electron flow in the conductor, and the fact that very powerful electromagnets can be formed with superconductors illustrates the tremendous advantage of producing the magnetic field by unpaired electron spins rather than conventional electron flow. In a superconducting metal, wherein the electrical resistance becomes greater in the metal than the proton resistance, the flow turns to electron spins and the positive particles flow parallel in the metal in the manner occurring in a permanent magnet where a powerful flow of magnetic positive particles or magnetic flux causes the unpaired electrons to spin at right angles. Under cryogenic superconduction conditions the freezing of the crystals in place makes it possible for the spins to continue, and in a permanent magnet the grain orientation of the magnetised material allows these spins, permitting them to continue and causing the flux to flow parallel to the metal. In a superconductor, at first the electron is flowing and the positive particle is spinning; later, when critical, the reverse occurs, i.e., the electron is spinning and the positive particle is flowing at right angles. These positive particles will thread or work their way through the electron spins present in the metal.

In a sense, a permanent magnet may be considered a room-temperature superconductor. It is a superconductor because the electron flow does not cease, and this electron flow can be made to do work through the magnetic field which it creates. Previously, this source of power has not been used because it was not possible to modify the electron flow to accomplish the switching functions of the magnetic field. Such switching functions are common in a conventional electric motor where electrical current is employed to align the much greater electron current in the iron pole pieces and concentrate the magnetic field at the proper places to give the thrust necessary to move the motor armature. In a conventional electric motor, switching is accomplished by the use of brushes, commutators, alternating current, or other means.

In order to accomplish the switching function in a permanent magnet motor, it is necessary to shield the magnetic leakage so that it will not appear as too great a loss factor at the wrong places. The best method to accomplish this is to concentrate the magnetic flux in the place where it will be the most effective. Timing and switching can be achieved in a permanent magnet motor by concentrating the flux and using the proper geometry of the motor rotor and stator to make most effective use of the magnetic fields. By the proper combination of materials, geometry and magnetic concentration, it is possible to achieve a mechanical advantage of high ratio, greater than 100 to 1, capable of producing continuous motive force.

To my knowledge, previous work done with permanent magnets, and motive devices utilising permanent magnets, have not achieved the result desired in the practice of the inventive concept, and it is with the proper combination of materials, geometry and magnetic concentration that the presence of the magnetic spins within a permanent magnet may be utilised as a motive force.

SUMMARY OF THE INVENTION:

It is an object of the invention to utilise the magnetic spinning phenomenon of unpaired electrons occurring in ferromagnetic material to produce the movement of a mass in a unidirectional manner so as to permit a motor to be driven solely by the magnetic forces occurring within permanent magnets. Both linear and rotational types of motor may be produced. It is an object of the invention to provide the proper combination of materials, geometry and magnetic concentration to power a motor. Whether the motor is a linear type or a rotary type, in each instance the "stator" may consist of several permanent magnets fixed relative to each other, to create a track. This track is linear for a linear motor and circular for a rotary motor. An armature magnet is carefully positioned above this track so that an air gap exists between it and the track. The length of the armature magnet is defined by poles of opposite polarity, and the longer axis of the armature magnet is pointed in the direction of its movement.

The stator magnets are mounted so that all the same poles face the armature magnet. The armature magnet has poles which are both attracted to and repelled by the adjacent pole of the stator magnets, so both attractive and repulsive forces act upon the armature magnet to make it move.

The continuing motive force which acts on the armature magnet is caused by the relationship of the length of the armature magnet to the width and spacing of the stator magnets. This ratio of magnet and magnet spacings, and with an acceptable air gap spacing between the stator and armature magnets, produces a continuous force which causes the movement of the armature magnet.

In the practice of the invention, movement of the armature magnet relative to the stator magnets results from a combination of attractive and repulsive forces between the stator and armature magnets. By concentrating the magnetic fields of the stator and armature magnets the motive force imposed upon the armature magnet is intensified, and in the disclosed embodiments, the means for achieving this magnetic field concentration are shown.

This method comprises of a plate of high magnetic field permeability placed behind one side of the stator magnets and solidly engaged with them. The magnetic field of the armature magnet may be concentrated and directionally oriented by bowing the armature magnet, and the magnetic field may further be concentrated by shaping the pole ends of the armature magnet to concentrate the magnet field at a relatively limited surface at the armature magnet pole ends.

Preferably, several armature magnets are used and these are staggered relative to each other in the direction their movement. Such an offsetting or staggering of the armature magnets distributes the impulses of force imposed upon the armature magnets and results in a smoother application of forces to the armature magnet producing a smoother and more uniform movement of the armature component.

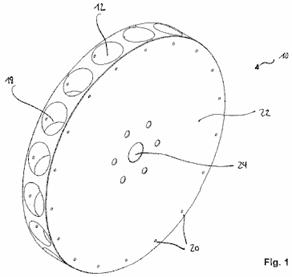

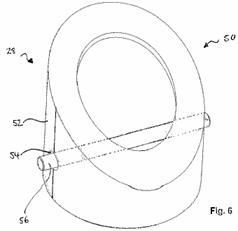

In the rotary embodiment of the permanent magnet motor of the invention the stator magnets are arranged in a circle, and the armature magnets rotate about the stator magnets. A mechanism is shown which can move the armature relative to the stator and this controls the magnitude of the magnetic forces, altering the speed of rotation of the motor.

BRIEF DESCRIPTION OF THE DRAWINGS

The objects and advantages of the invention mentioned earlier, will be appreciated from the following description and accompanying drawings:

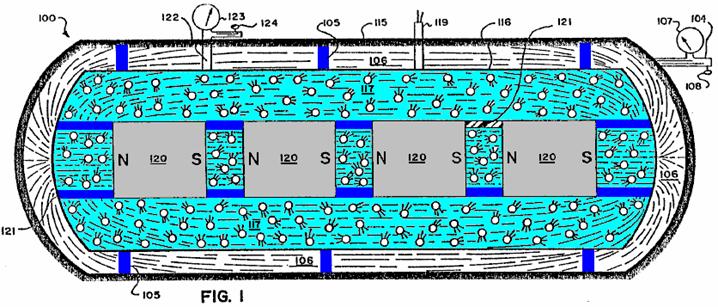

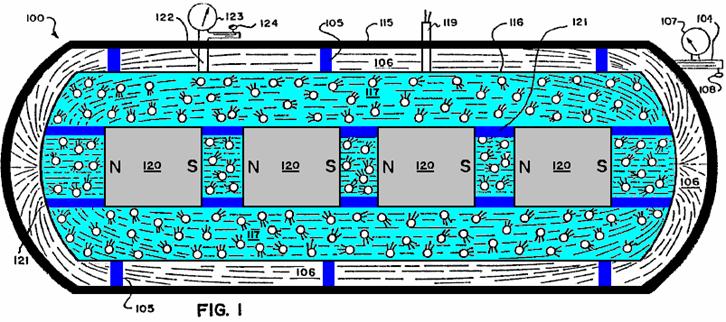

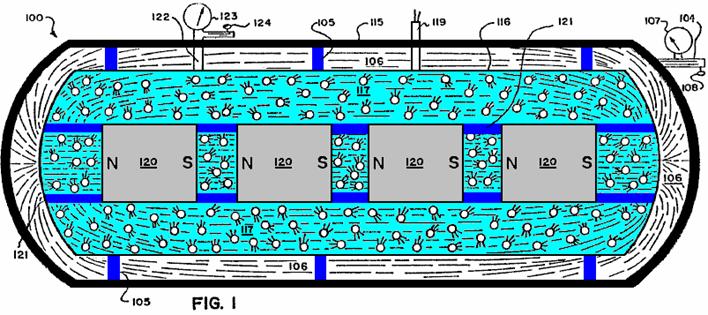

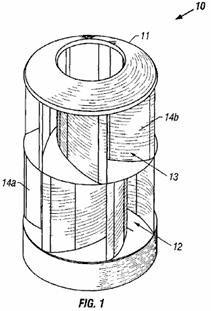

Fig. 1 is a schematic view of electron flow in a superconductor indicating the unpaired electron spins,

Fig. 2 is a cross-sectional view of a superconductor under a critical state illustrating the electron spins,

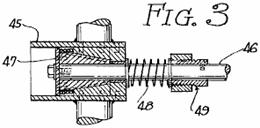

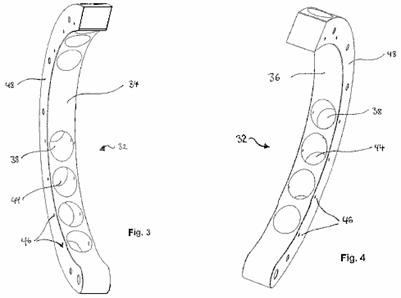

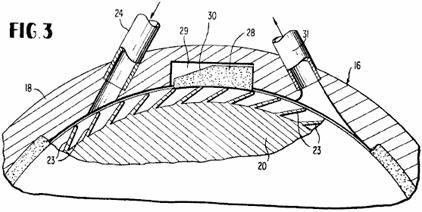

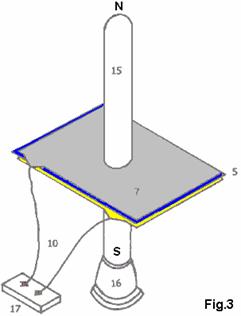

Fig. 3 is a view of a permanent magnet illustrating the flux movement through it,

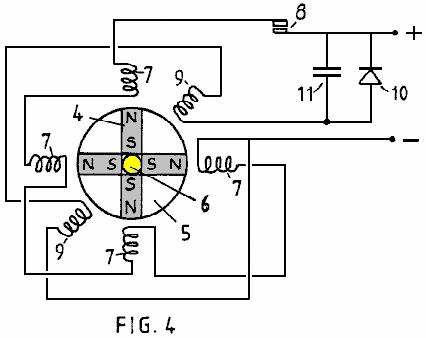

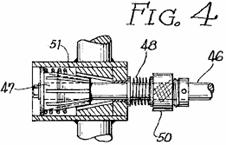

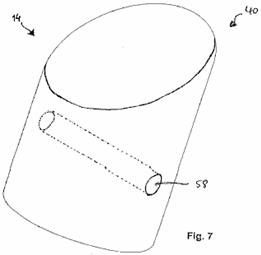

Fig. 4 is a cross-sectional view illustrating the diameter of the magnet of Fig.3,

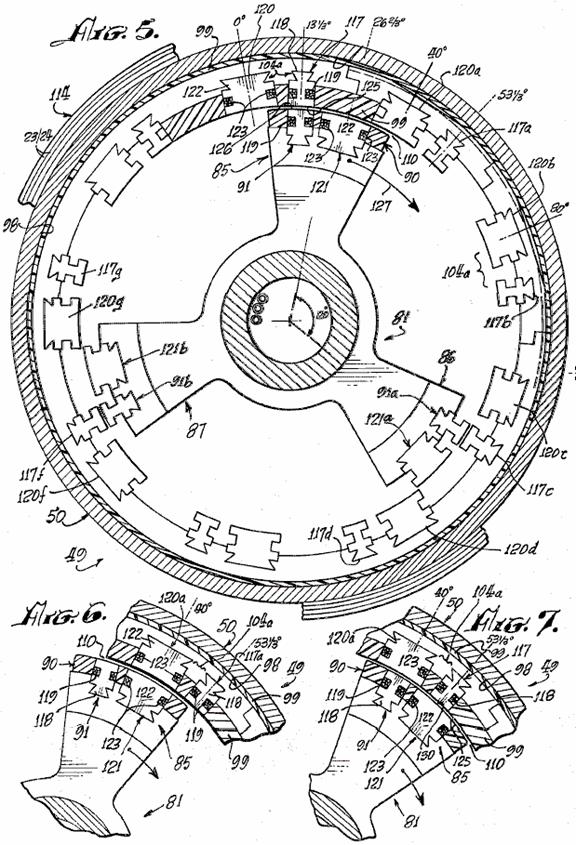

Fig. 5 is an elevational representation of a linear motor embodiment of the permanent magnet motor of the invention illustrating one position of the armature magnet relative to the stator magnets, and indicating the magnetic forces imposed upon the armature magnet,

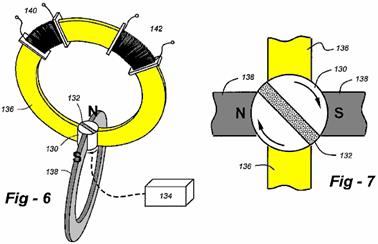

Fig. 6 is a view similar to Fig.5

illustrating displacement of the armature magnet relative to the stator

magnets, and the influence of magnetic forces thereon at this location,

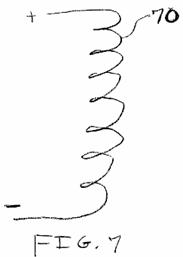

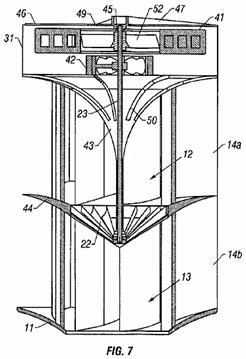

Fig. 7 is a further elevational view similar to Fig.5 and Fig.6 illustrating further displacement of the armature magnet to the left, and the influence of the magnetic forces thereon,

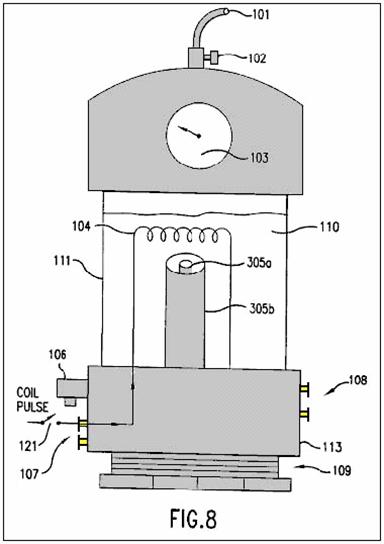

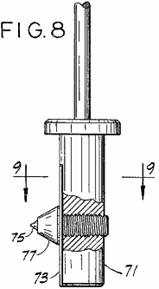

Fig. 8 is a top plan view of a linear embodiment of the inventive concept illustrating a pair of armature magnets in linked relationship disposed above the stator magnets,

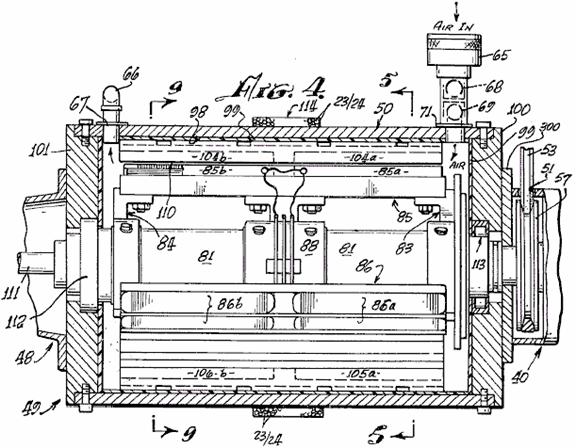

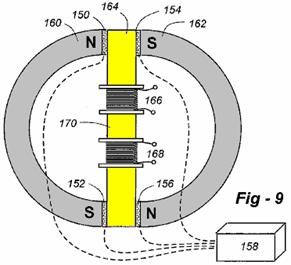

Fig. 9 is a diametrical, elevational, sectional view of a rotary motor embodiment in accord with the invention as taken along section IX-IX of Fig.10, and

Fig. 10 is an elevational view of the rotary motor embodiment as taken along X-X of Fig.9.

DESCRIPTION OF THE PREFERRED EMBODIMENTS

In order to better understand the theory of the inventive concept, reference is made to Figs. 1 through 4. In Fig.1 a superconductor 1 is illustrated having a positive particle flow as represented by arrow 2, the unpaired electrons of the ferrous conductor 1 spin at right angles to the proton flow in the conductor as represented by the spiral line and arrow 3. In accord with the theory of the invention the spinning of the ferrous unpaired electrons results from the atomic structure of ferrous materials and this spinning atomic particle is believed to be opposite in charge and located at right angles to the moving electrons. It is assumed to be very small in size capable of penetrating other elements and their compounds unless they have unpaired electrons which capture these particles as they endeavour to pass through.

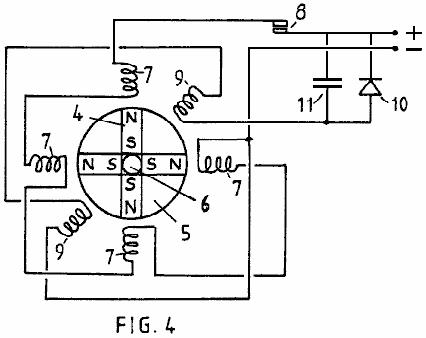

The lack of electrical resistance of conductors at a critical superconductor state has long been recognised, and superconductors have been utilised to produce very high magnetic flux density electromagnets. Fig.2 represents a cross section of a critical superconductor and the electron spins are indicated by the arrows 3. A permanent magnet may be considered a superconductor as the electron flow therein does not cease, and is without resistance, and unpaired electric spinning particles exist which, in the practice of the invention, are utilised to produce motor force. Fig.3 illustrates a horseshoe shaped permanent magnet at 4 and the magnetic flux through it is indicated by arrows 5, the magnetic flow being from the south pole to the north pole and through the magnetic material. The accumulated electron spins occurring about the diameter of the magnet 5 are represented at 6 in Fig.4, and the spinning electron particles spin at right angles in the iron as the flux travels through the magnet material.

By utilising the electron spinning theory of ferrous material electrons, it is possible with the proper ferromagnetic materials, geometry and magnetic concentration to utilise the spinning electrons to produce a motive force in a continuous direction, thereby resulting in a motor capable of doing work.

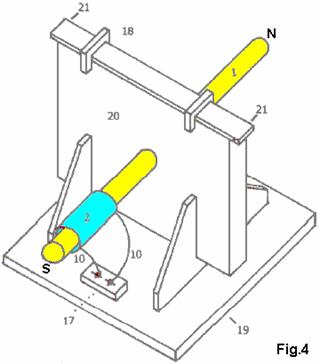

It is appreciated that the embodiments of motors utilising the concepts of the invention may take many forms, and in the illustrated forms the basic relationships of components are illustrated in order to disclose the inventive concepts and principles. The relationships of the plurality of magnets defining the stator 10 are best appreciated from Figs. 5 through 8. The stator magnets 12 are preferably of a rectangular configuration, Fig.8, and so magnetised that the poles exist at the large surfaces of the magnets, as will be appreciated from the N (North) and S (South) designations. The stator magnets include side edges 14 and 16 and end edges 18. The stator magnets are mounted upon a supporting plate 20, which is preferably of a metal having a high permeability to magnetic fields and magnetic flux such as that available under the trademark Netic CoNetic sold by Perfection Mica Company of Chicago, Illinois. Thus, the plate 20 will be disposed toward the south pole of the stator magnets 12, and preferably in direct engagement therewith, although a bonding material may be interposed between the magnets and the plate in order to accurately locate and fix the magnets on the plate, and position the stator magnets with respect to each other.

Preferably, the spacing between the stator magnets 12 slightly differs between adjacent stator magnets as such a variation in spacing varies the forces being imposed upon the armature magnet at its ends, at any given time, and thus results in a smoother movement of the armature magnet relative to the stator magnets. Thus, the stator magnets so positioned relative to each other define a track 22 having a longitudinal direction left to right as viewed in Figs. 5 through 8.

In Figs. 5 through 7 only a single armature magnet 24 is disclosed, while in Fig.8 a pair of armature magnets are shown. For purposes of understanding the concepts of the invention the description herein will be limited to the use of single armature magnet as shown in Figs. 5 through 7.

The armature magnet is of an elongated configuration wherein the length extends from left to right, Fig.5, and may be of a rectangular transverse cross-sectional shape. For magnetic field concentrating and orientation purposes the magnet 24 is formed in an arcuate bowed configuration as defined by concave surfaces 26 and convex surfaces 28, and the poles are defined at the ends of the magnet as will be appreciated from Fig.5. For further magnetic field concentrating purposes the ends of the armature magnet are shaped by bevelled surfaces 30 to minimise the cross sectional area at the magnet ends 32, and the magnetic flux existing between the poles of the armature magnet are as indicated by the light dotted lines. In like manner the magnetic fields of 6 the stator magnets 12 are indicated by the light dotted lines.

The armature magnet 24 is maintained in a spaced relationship above the stator track 22. This spacing may be accomplished by mounting the armature magnet upon a slide, guide or track located above the stator magnets, or the armature magnet could be mounted upon a wheeled vehicle carriage or slide supported upon a non-magnetic surface or guideway disposed between the stator magnets and the armature magnet. To clarify the illustration, the means for supporting the armature magnet 24 is not illustrated and such means form no part of invention, and it is to be understood that the means supporting the armature magnet prevents the armature magnet from moving away from the stator magnets, or moving closer thereto, but permits free movement of the armature magnet to the left or right in a direction parallel to the track 22 defined by the stator magnets.

It will be noted that the length of the armature magnet 24 is slightly greater than the width of two of the stator magnets 12 and the spacing between them. The magnetic forces acting upon the armature magnet when in the position of Fig.5 will be repulsion forces 34 due to the proximity of like polarity forces and attraction forces at 36 because of the opposite polarity of the south pole of the armature magnet, and the north pole field of the sector magnets. The relative strength of this force is represented by the thickness of the force line.

The resultant of the force vectors imposed upon the armature magnet as shown in Fig.5 produce a primary force vector 38 toward the left, Fig.5, displacing the armature magnet 24 toward the left. In Fig.6 the magnetic forces acting upon the armature magnet are represented by the same reference numerals as in Fig.5. While the forces 34 constitute repulsion forces tending to move the north pole of the armature magnet away from the stator magnets, the attraction forces imposed upon the south pole of the armature magnet and some of the repulsion forces, tend to move the armature magnet further to the left, and as the resultant force 38 continues to be toward the left the armature magnet continues to be forced to the left. Fig.7 represents further displacement of the armature magnet 24 to the left with respect to the position of Fig.6, and the magnetic forces acting thereon are represented by the same reference numerals as in Fig.5 and Fig.6, and the stator magnet will continue to move to the left, and such movement continues the length of the track 22 defined by the stator magnets 12.

Upon the armature magnet being reversed such that the north pole is positioned at the right as viewed in Fig.5, and the south pole is positioned at the left, the direction of movement of the armature magnet relative to the stator magnets is toward the right, and the theory of movement is identical to that described above.

In Fig.8 a plurality of armature magnets 40 and 42 are illustrated which are connected by links 44. The armature magnets are of a shape and configuration identical to that of the embodiment of Fig.5, but the magnets are staggered with respect to each other in the direction of magnet movement, i.e., the direction of the track 22 defined by the stator magnets 12. By so staggering a plurality of armature magnets a smoother movement of the interconnected armature magnets is produced as compared when using a single armature magnet as there is variation in the forces acting upon each armature magnet as it moves above the track 22 due to the change in magnetic forces imposed thereon. The use of several armature magnets tends to "smooth out" the application of forces imposed upon linked armature magnets, resulting in a smoother movement of the armature magnet assembly. Of course, any number of armature magnets may be interconnected, limited only by the width of the stator magnet track 22.

In Fig.9 and Fig.10 a rotary embodiment embracing the inventive concepts is illustrated. In this embodiment the principle of operation is identical to that described above, but the orientation of the stator and armature magnets is such that rotation of the armature magnets is produced about an axis, rather than a linear movement being achieved.

In Fig.9 and Fig.10 a base is represented at 46 serving as a support for a stator member 48. The stator member 48 is made of a non-magnetic material, such as synthetic plastic, aluminium, or the like. The stator includes a cylindrical surface 50 having an axis, and a threaded bore 52 is concentrically defined in the stator. The stator includes an annular groove 54 receiving an annular sleeve 56 of high magnetic field permeability material such as Netic Co-Netic and a plurality of stator magnets 58 are affixed upon the sleeve 56 in spaced circumferential relationship as will be apparent in Fig.10. Preferably, the stator magnets 58 are formed with converging radial sides as to be of a wedge configuration having a curved inner surface engaging sleeve 56, and a convex pole surface 60.

The armature 62, in the illustrated embodiment, is of a dished configuration having a radial web portion, and an axially extending portion 64. The armature 62 is formed of a non-magnetic material, and an annular belt receiving groove 66 is defined therein for receiving a belt for transmitting power from the armature to a generator, or other power consuming device. Three armature magnets 68 are mounted on the armature portion 64, and such magnets are of a configuration similar to the armature magnet configuration of Figs. 5 through 7.

The magnets 68 are staggered with respect to each other in a circumferential direction wherein the magnets are not placed exactly 120 degrees apart but instead, a slight angular staggering of the armature magnets is desirable to "smooth out" the magnetic forces being imposed upon the armature as a result of the magnetic forces being simultaneously imposed upon each of the armature magnets. The staggering of the armature magnets 68 in a circumferential direction produces the same effect as the staggering of the armature magnets 40 and 42 as shown in Fig.8.

The armature 62 is mounted upon a threaded shaft 70 by anti-friction bearings 72, and the shaft 70 is threaded into the stator threaded bore 52, and may be rotated by the knob 74. In this manner rotation of the knob 74, and shaft 70, axially displaces the armature 62 with respect to the stator magnets 58, and such axial displacement will very the magnitude of the magnetic forces imposed upon the armature magnets 68 by the stator magnets thereby controlling the speed of rotation of the armature. As will be noted from Figs. 4 to 7, 9 and 10, an air gap exists between the armature magnets and the stator magnets and the dimension of this spacing, effects the magnitude of the forces imposed upon the armature magnet or magnets. If the distance between the armature magnets and the stator magnets is reduced the forces imposed upon the armature magnets by the stator magnets are increased, and the resultant force 8 vector tending to displace the armature magnets in their path of movement increases. However, the decreasing of the spacing between the armature and stator magnets creates a "pulsation" in the movement of the armature magnets which is objectionable, but can be, to some extent, minimised by using a plurality of armature magnets. Increasing the distance between the armature and stator magnets reduces the pulsation tendency of the armature magnet, but also reduces the magnitude of the magnetic forces imposed upon the armature magnets. Thus, the most effective spacing between the armature and stator magnets is that spacing which produces the maximum force vector in the direction of armature magnet movement, with a minimum creation of objectionable pulsation.

In the disclosed embodiments the high permeability plate 20 and sleeve 56 are disclosed for concentrating the magnetic field of the stator magnets, and the armature magnets are bowed and have shaped ends for magnetic field concentration purposes. While such magnetic field concentration means result in higher forces imposed upon the armature magnets for given magnet intensities, it is not intended that the inventive concepts be limited to the use of such magnetic field concentrating means.

As will be appreciated from the above description of the invention, the movement of the armature magnet or magnets results from the described relationship of components. The length of the armature magnets as related to the width of the stator magnets and spacing between them, the dimension of the air gap and the configuration of the magnetic field, combined, produce the desired result and motion. The inventive concepts may be practised even though these relationships may be varied within limits not yet defined and the invention is intended to encompass all dimensional relationships which achieve the desired goal of armature movement. By way of example, with respect to Figs. to 7, the following dimensions were used in an operating prototype:

The length of armature magnet 24 is 3.125", the stator magnets 12 are 1" wide, .25" thick and 4" long and grain oriented. The air gap between the poles of the armature magnet and the stator magnets is approximately 1.5" and the spacing between the stator magnets is approximately .5" inch.

In effect, the stator magnets define a magnetic field track of a single polarity transversely interrupted at spaced locations by the magnetic fields produced by the lines of force existing between the poles of the stator magnets and the unidirectional force exerted on the armature magnet is a result of the repulsion and attraction forces existing as the armature magnet traverses this magnetic field track.

It is to be understood that the inventive concept embraces an arrangement wherein the armature magnet component is stationary and the stator assembly is supported for movement and constitutes the moving component, and other variations of the inventive concept will be apparent to those skilled in the art without departing from the scope thereof. As used herein the term "track" is intended to include both linear and circular arrangements of the static magnets, and the "direction" or "length" of the track is that direction parallel or concentric to the intended direction of armature magnet movement.

PAVEL IMRIS: OPTICAL GENERATOR

US Patent

3,781,601 25th December

1973 Inventor: Pavel Imris

OPTICAL GENERATOR OF AN ELECTROSTATIC

FIELD HAVING LONGITUDINAL OSCILLATION AT LIGHT FREQUENCIES FOR USE IN AN

ELECTRICAL CIRCUIT

Please note

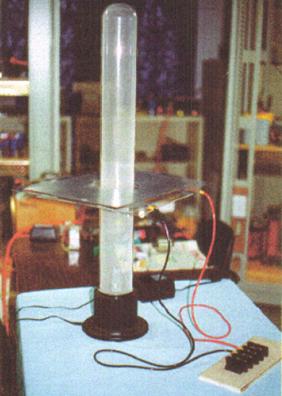

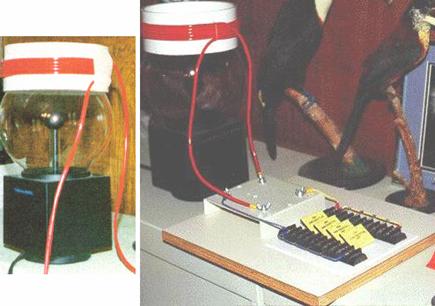

that this is a re-worded excerpt from this patent. It describes a gas-filled tube which allows

many standard 40-watt fluorescent tubes to be powered using less than 1-watt of

power each.

ABSTRACT

An Optical generator of an electrostatic field at light frequencies for use in an electrical circuit, the generator having a pair of spaced-apart electrodes in a gas-filled tube of quartz glass or similar material with at least one capacitor cap or plate adjacent to one electrode and a dielectric filled container enclosing the tube, the generator substantially increasing the electrical efficiency of the electrical circuit.

BACKGROUND OF THE INVENTION

This invention relates to improved electrical circuits, and more particularly to circuits utilising an optical generator of an electrostatic field at light frequencies.

The measure of the efficiency of an electrical circuit may broadly be defined as the ratio of the output energy in the desired form (such as light in a lighting circuit) to the input electrical energy. Up to now, the efficiency of many circuits has not been very high. For example, in a lighting circuit using 40 watt fluorescent lamps, only about 8.8 watts of the input energy per lamp is actually converted to visible light, thus representing an efficiency of only about 22%. The remaining 31.2 watts is dissipated primarily in the form of heat.

It has been suggested that with lighting circuits having fluorescent lamps, increasing the frequency of the applied current will raise the overall circuit efficiency. While at an operating frequency of 60 Hz, the efficiency is 22%, if the frequency is raised to 1 Mhz, the circuit efficiency would only rise to some 25.5%. Also, if the input frequency were raised to 10 Ghz, the overall circuit efficiency would only be 35%.

SUMMARY OF THE PRESENT INVENTION

The present invention utilises an optical electrostatic generator which is effective for producing high frequencies in the visible light range of about 1014 to 1023 Hz. The operation and theory of the optical electrostatic generator has been described and discussed in my co-pending application serial No. 5,248, filed on 23rd January 1970. As stated in my co-pending application, the present optical electrostatic generator does not perform in accordance with the accepted norms and standards of ordinary electromagnetic frequencies.

The optical electrostatic generator as utilised in the present invention can generate a wide range of frequencies between several Hertz and those in the light frequency. Accordingly, it is an object of the present invention to provide improved electrical energy circuits utilising my optical electrostatic generator, whereby the output energy in the desired form will be substantially more efficient than possible to date, using standard circuit techniques and equipment. It is a further object of the present invention to provide such a circuit for use in fluorescent lighting or other lighting circuits. It is also an object of the present invention to provide a circuit with may be used in conjunction with electrostatic precipitators for dust and particle collection and removal, as well as many other purposes.

DESCRIPTION OF THE DRAWINGS

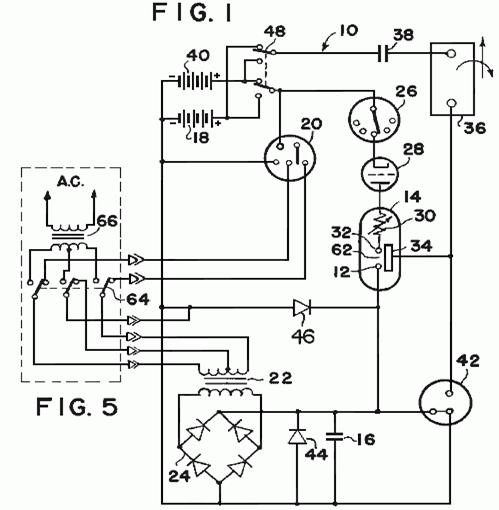

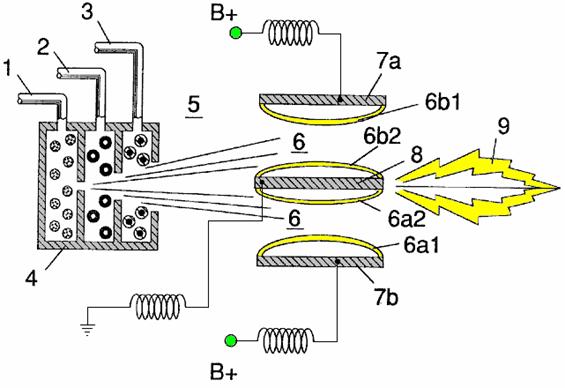

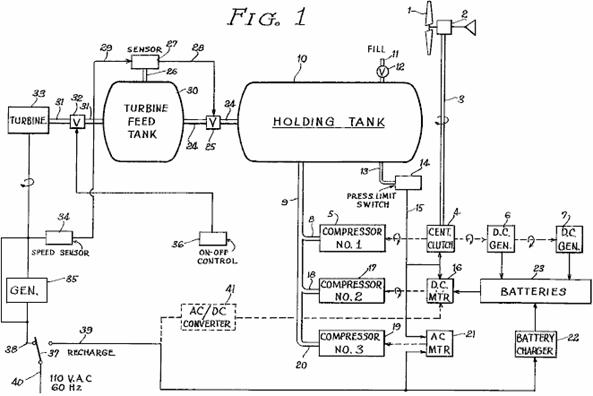

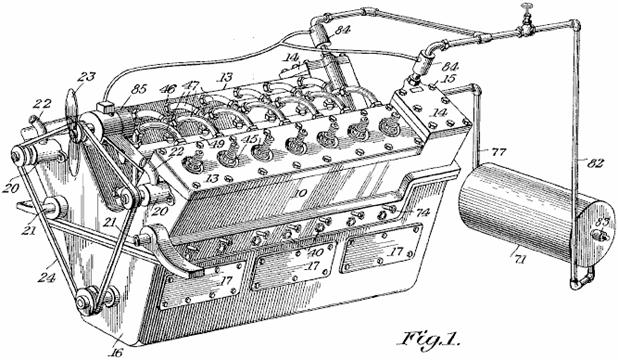

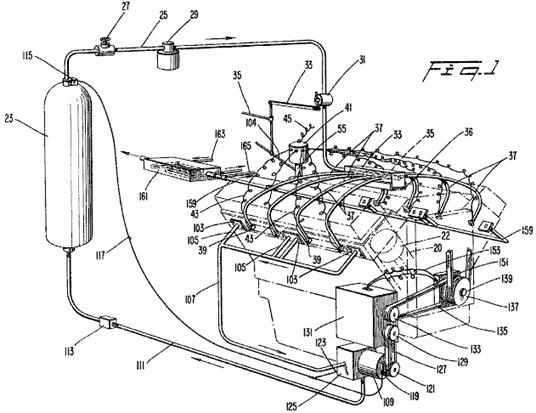

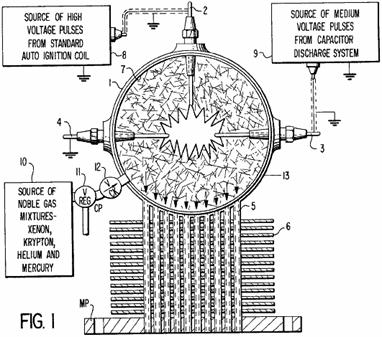

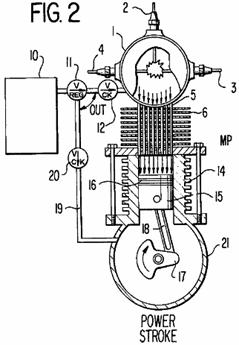

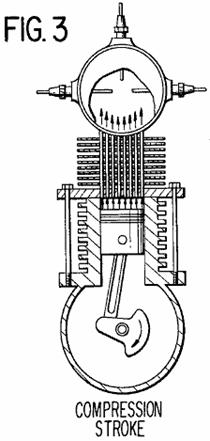

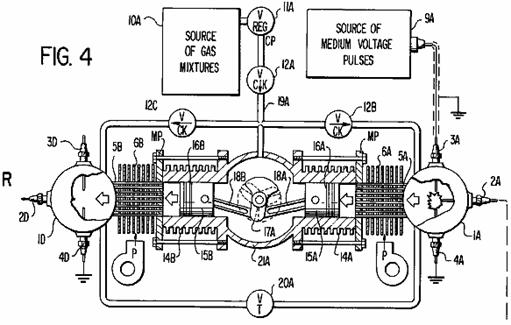

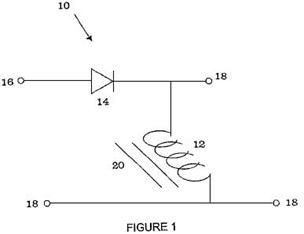

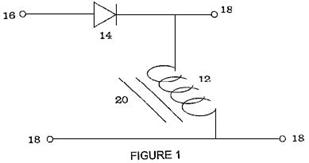

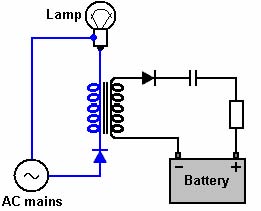

Fig.1 is a schematic layout showing an optical electrostatic generator of the present invention, utilised in a lighting circuit for fluorescent lamps:

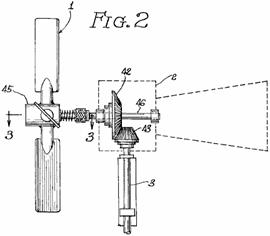

Fig.2 is a schematic layout of a high-voltage circuit incorporating an optical electrostatic generator:

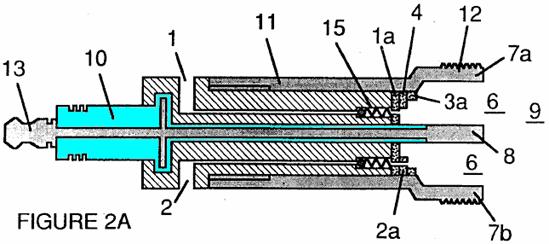

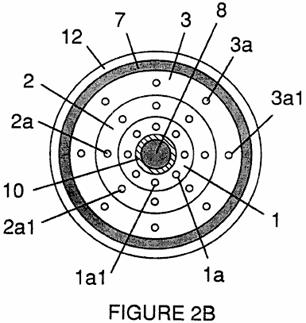

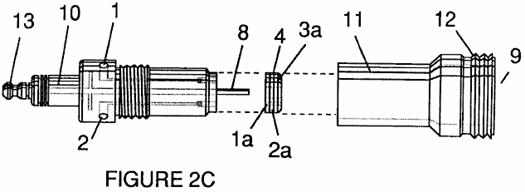

Fig.2A is a sectional view through a portion of the generator and

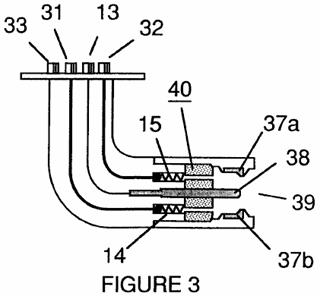

Fig.3 is a schematic sectional view showing an optical electrostatic generator in accordance with the present invention, particularly for use in alternating current circuits, although it may also be used in direct current circuits:

DESCRIPTION OF THE ILLUSTRATED EMBODIMENTS

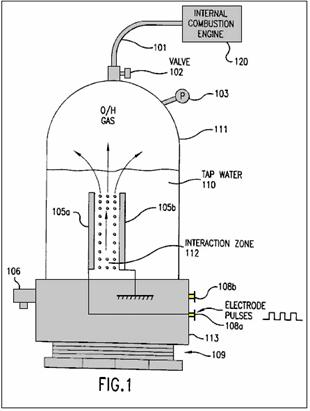

Referring to the drawings and to Fig.1 in particular, a low voltage circuit utilising an optical electrostatic generator is shown. As shown in Fig.1, a source of alternating current electrical energy 10, is connected to a lighting circuit. Connected to one tap of the power source 10 is a rectifier 12 for utilisation when direct current is required. The illustrated circuit is provided with a switch 14 which may be opened or closed depending on whether AC or DC power is used. Switch 14 is opened and a switch 16 is closed when AC is used. With switch 14 closed and switch 16 open, the circuit operates as a DC circuit.

Extending from switches 14 and 16 is conductor 18 which is connected to an optical electrostatic generator 20. Conductor 18 is passed through an insulator 22 and connected to an electrode 24. Spaced from electrode 24 is a second electrode 25. Enclosing electrodes 24 and 25, which preferably are made of tungsten or similar material, is a quartz glass tube 26 which is filled with an ionisable gas 28 such as xenon or any other suitable ionisable gas such as argon, krypton, neon, nitrogen or hydrogen, as well as the vapour of metals such as mercury or sodium.

Surrounding each end of tube 26 and adjacent to electrodes 24 and 25, are capacitor plates 30 and 32 in the form of caps. A conductor is connected to electrode 25 and passed through a second insulator 34. Surrounding the tube, electrodes and capacitor caps is a metal envelope in the form of a thin sheet of copper or other metal such as aluminium. Envelope 36 is spaced from the conductors leading into and out of the generator by means of insulators 22 and 34. Envelope 36 is filled with a dielectric material such as transformer oil, highly purified distilled water, nitro-benzene or any other suitable liquid dielectric. In addition, the dielectric may be a solid such as ceramic material with relatively small molecules.

A conductor 40 is connected to electrode 25, passed through insulator 24 and then connected to a series of fluorescent lamps 42 which are connected in series. It is the lamps 42 which will be the measure of the efficiency of the circuit containing the optical electrostatic generator 20. A conductor 44 completes the circuit from the fluorescent lamps to the tap of the source of electrical energy 10. In addition, the circuit is connected to a ground 46 by another conductor 48. Envelope 36 is also grounded by lead 50 and in the illustrated diagram, lead 50 is connected to the conductor 44.

The capacitor caps or plates 30 and 32, form a relative capacitor with the discharge tube. When a high voltage is applied to the electrode of the discharge tube, the ions of gas are excited and brought to a higher potential than their environment, i.e. the envelope and the dielectric surrounding it. At this point, the ionised gas in effect becomes one plate of a relative capacitor in co-operation with the capacitor caps or plates 30 and 32.

When this relative capacitor is discharged, the electric current does not decrease as would normally be expected. Instead, it remains substantially constant due to the relationship between the relative capacitor and an absolute capacitor which is formed between the ionised gas and the spaced metal envelope 36. An oscillation effect occurs in the relative capacitor, but the electrical condition in the absolute capacitor remains substantially constant.

As also described in the co-pending application serial No. 5,248, there is an oscillation effect between the ionised gas in the discharge lamp and the metallic envelope 36 will be present if the capacitor caps are eliminated, but the efficiency of the electrostatic generator will be substantially decreased.

The face of the electrode can be any desired shape. However, a conical point of 600 has been found to be satisfactory and it is believed to have an influence on the efficiency of the generator.

In addition, the type of gas selected for use in tube 26, as well as the pressure of the gas in the tube, also affect the efficiency of the generator, and in turn, the efficiency of the electrical circuit.

To demonstrate the increased efficiency of an electrical circuit utilising the optical electrostatic generator of the present invention as well as the relationship between gas pressure and electrical efficiency, a circuit similar to that shown in Fig.1 may be used with 100 standard 40 watt, cool-white fluorescent lamps connected in series. The optical electrostatic generator includes a quartz glass tube filled with xenon, with a series of different tubes being used because of the different gas pressures being tested.

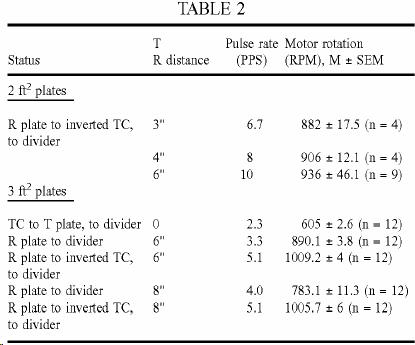

Table 1 shows the data to be obtained relating to the optical electrostatic generator. Table 2 shows the lamp performance and efficiency for each of the tests shown in Table 1. The following is a description of the data in each of the columns of Tables 1 and 2.

|

Column |

Description |

|

B |

Gas used in discharge tube |

|

C |

Gas pressure in tube (in torrs) |

|

D |

Field strength across the tube (measured in volts per cm. of length between the electrodes) |

|

E |

Current density (measured in microamps per sq. mm. of tube cross-sectional area) |

|

F |

Current (measured in amps) |

|

G |

Power across the tube (calculated in watts per cm. of length between the electrodes) |

|

H |

Voltage per lamp (measured in volts) |

|

K |

Current (measured in amps) |

|

L |

Resistance (calculated in ohms) |

|

M |

Input power per lamp (calculated in watts) |

|

N |

Light output (measured in lumens) |

Table 1

|

|

|

Optical |

Generator |

Section |

|

|

|

A |

B |

C |

D |

E |

F |

G |

|

Test No. |

Type of discharge

lamp |

Pressure of Xenon |

Field strength across lamp |

Current density |

Current |

Power str. across lamp |

|

|

|

(Torr) |

(V/cm) |

(A/sq.mm) |

(A) |

(W/cm.) |

|

1 |

Mo elec |

- |

- |

- |

- |

- |

|

2 |

Xe |

0.01 |

11.8 |

353 |

0.1818 |

2.14 |

|

3 |

Xe |

0.10 |

19.6 |

353 |

0.1818 |

3.57 |

|

4 |

Xe |

1.00 |

31.4 |

353 |

0.1818 |

5.72 |

|

5 |

Xe |

10.00 |

47.2 |

353 |

0.1818 |

8.58 |

|

6 |

Xe |

20.00 |

55.1 |

353 |

0.1818 |

10.02 |

|

7 |

Xe |

30.00 |

62.9 |

353 |

0.1818 |

11.45 |

|

8 |

Xe |

40.00 |

66.9 |

353 |

0.1818 |

12.16 |

|

9 |

Xe |

60.00 |

70.8 |

353 |

0.1818 |

12.88 |

|

10 |

Xe |

80.00 |

76.7 |

353 |

0.1818 |

13.95 |

|

11 |

Xe |

100.00 |

78.7 |

353 |

0.1818 |

14.31 |

|

12 |

Xe |

200.00 |

90.5 |

353 |

0.1818 |

16.46 |

|

13 |

Xe |

300.00 |

100.4 |

353 |

0.1818 |

18.25 |

|

14 |

Xe |

400.00 |

106.3 |

353 |

0.1818 |

19.32 |

|

15 |

Xe |

500.00 |

110.2 |

353 |

0.1818 |

20.04 |

|

16 |

Xe |

600.00 |

118.1 |

353 |

0.1818 |

21.47 |

|

17 |

Xe |

700.00 |

120.0 |

353 |

0.1818 |

21.83 |

|

18 |

Xe |

800.00 |

122.8 |

353 |

0.1818 |

22.33 |

|

19 |

Xe |

900.00 |

125.9 |

353 |

0.1818 |

22.90 |

|

20 |

Xe |

1,000.00 |

127.9 |

353 |

0.1818 |

23.26 |

|

21 |

Xe |

2,000.00 |

149.6 |

353 |

0.1818 |

27.19 |

|

22 |

Xe |

3,000.00 |

161.4 |

353 |

0.1818 |

29.35 |

|

23 |

Xe |

4,000.00 |

173.2 |

353 |

0.1818 |

31.49 |

|

24 |

Xe |

5,000.00 |

179.1 |

353 |

0.1818 |

32.56 |

Table 2

|

|

|

Fluorescent |

Lamp |

Section |

|

|

A |

H |

K |

L |

M |

N |

|

Test No. |

Voltage |

Current |

Resistance |

Input Energy |

Light Output |

|

|

(Volts) |

(Amps) |

(Ohms) |

( |

(Lumen) |

|

1 |

220 |

0.1818 |

1,210 |

40.00 |

3,200 |

|

2 |

218 |

0.1818 |

1,199 |

39.63 |

3,200 |

|

3 |

215 |

0.1818 |

1,182 |

39.08 |

3,200 |

|

4 |

210 |

0.1818 |

1,155 |

38.17 |

3,200 |

|

5 |

200 |

0.1818 |

1,100 |

36.36 |

3,200 |

|

6 |

195 |

0.1818 |

1,072 |

35.45 |

3,200 |

|

7 |

190 |

0.1818 |

1,045 |

34.54 |

3,200 |

|

8 |

182 |

0.1818 |

1,001 |

33.08 |

3,200 |

|

9 |

175 |

0.1818 |

962 |

31.81 |

3,200 |

|

10 |

162 |

0.1818 |

891 |

29.45 |

3,200 |

|

11 |

155 |

0.1818 |

852 |

28.17 |

3,200 |

|

12 |

130 |

0.1818 |

715 |

23.63 |

3,200 |

|

13 |

112 |

0.1818 |

616 |

20.36 |

3,200 |

|

14 |

100 |

0.1818 |

550 |

18.18 |

3,200 |

|

15 |

85 |

0.1818 |

467 |

15.45 |

3,200 |

|

16 |

75 |

0.1818 |

412 |

13.63 |

3,200 |

|

17 |

67 |

0.1818 |

368 |

12.18 |

3,200 |

|

18 |

60 |

0.1818 |

330 |

10.90 |

3,200 |

|

19 |

53 |

0.1818 |

291 |

9.63 |

3,200 |

|

20 |

50 |

0.1818 |

275 |

9.09 |

3,200 |

|

21 |

23 |

0.1818 |

126 |

4.18 |

3,200 |

|

22 |

13 |

0.1818 |

71 |

2.35 |

3,200 |

|

23 |

8 |

0.1818 |

44 |

1.45 |

3,200 |

|

24 |

5 |

0.1818 |

27 |

0.90 |

3,200 |

The design of a tube construction for use in the optical electrostatic generator of the type used in Fig.1, may be accomplished by considering the radius of the tube, the length between the electrodes in the tube and the power across the tube.

If R is the minimum inside radius of the

tube in centimetres, L the minimum

length in centimetres between the electrodes, and W the power in watts across the lamp, the following formula can be

obtained from Table 1:

R = (Current [A] / Current Density

[A/sq.mm] ) / pi

L = 8R

W = L[V/cm] x A

For example, for Test No. 18 in Table 1:

The current is 0.1818 A,

The current density 0.000353 A/sq.mm and

The Voltage Distribution is 122.8 V/cm; therefore

R = (0.1818 / 0.000353)2 /3.14 = 12.80 mm.

L = 8 x R = 8 * 12.8 = 102.4 mm (10.2 cm.)

W = 10.2 x 122.8 x 0.1818 = 227.7 VA or 227.7 watts

The percent efficiency of operation of the fluorescent lamps in Test No. 18 can be calculated from the following equation:

% Efficiency = (Output Energy/Input energy) x 100

Across a single fluorescent lamp, the voltage is 60 volts and the current is 0.1818 amps therefore the input energy to the lamp 42 is 10.90 Watts. The output of the fluorescent lamp is 3,200 lumens which represents 8.8 Watts power of light energy. Thus, the one fluorescent lamp is operating at 80.7% efficiency under these conditions.

However, when the optical generator is the same as described for Test No. 18 and there are 100 fluorescent lamps in series in the circuit, the total power input is 227.7 watts for the optical generator and 1,090 watts for 100 fluorescent lamps, or a total of 1,318 watts. The total power input normally required to operate the 100 fluorescent lamps in a normal circuit would be 100 x 40 = 4,000 watts. So by using the optical generator in the circuit, about 2,680 watts of energy is saved.

Table 1 is an example of the functioning of this invention for a particular fluorescent lamp (40 watt cool white). However, similar data can be obtained for other lighting applications, by those skilled in the art.

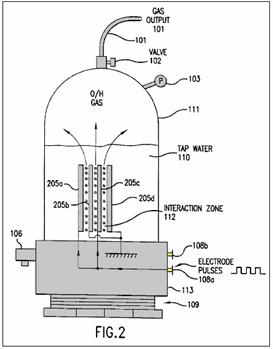

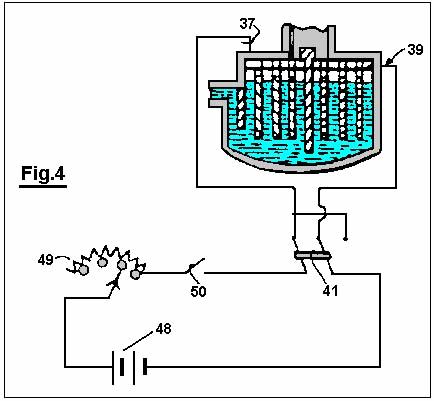

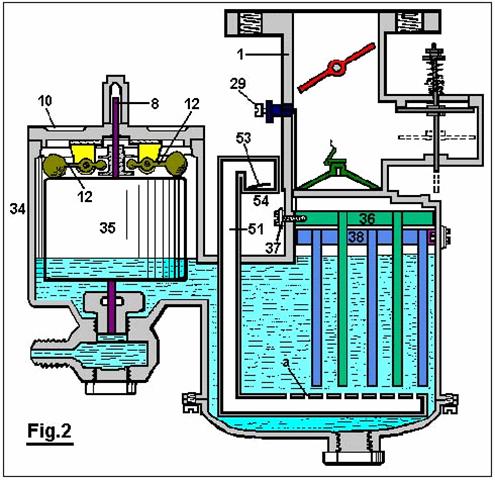

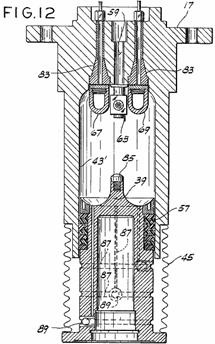

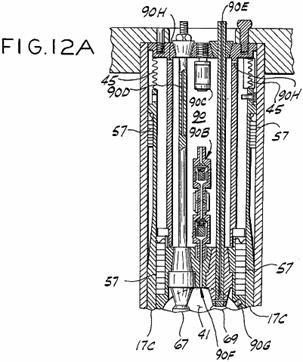

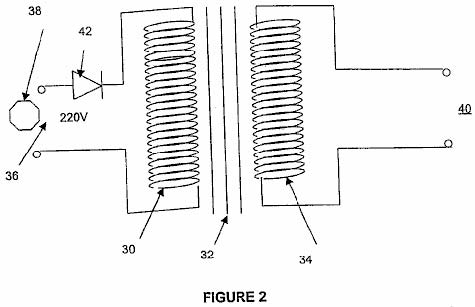

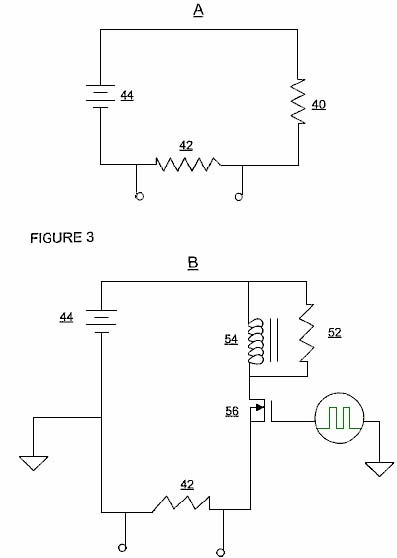

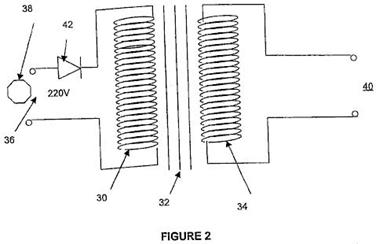

In Fig.2, a circuit is shown which uses an optical electrostatic generator 20a, similar to generator 20 of Fig.1. In generator 20, only one capacitor cap 32a is used and it is preferably of triangular cross-sectional design. In addition, the second electrode 25a is connected directly back into the return conductor 52, similar to the arrangement shown in my co-pending application serial No. 5,248, filed 23rd January 1970.

This arrangement is preferably for very high voltage circuits and the generator is particularly suited for DC usage.

In Fig.2, common elements have received the same numbers which were used in Fig.1.

In Fig.3, still another embodiment of an optical electrostatic generator 20b is shown. This generator is particularly suited for use with AC circuits. In this embodiment, the capacitor plates 30b and 32b have flanges 54 and 56 which extend outwards towards the envelope 36. While the utilisation of the optical electrostatic generator has been described in use in a fluorescent lighting circuit, it is to be understood that many other types of circuits may be used. For example, the high-voltage embodiment may be used in a variety of circuits such as flash lamps, high-speed controls, laser beams and high-energy pulses. The generator is also particularly usable in a circuit including electrostatic particle precipitation in air pollution control devices, chemical synthesis in electrical discharge systems such as ozone generators and charging means for high-voltage generators of the Van de Graff type, as well as particle accelerators. To those skilled in the art, many other uses and circuits will be apparent.

HAROLD COLMAN & RONALD SEDDON-GILLESPIE: 70-YEAR BATTERY

Patent GB 763,062 5th December 1956 Inventors: Harold Colman and Ronald Seddon-Gillespie

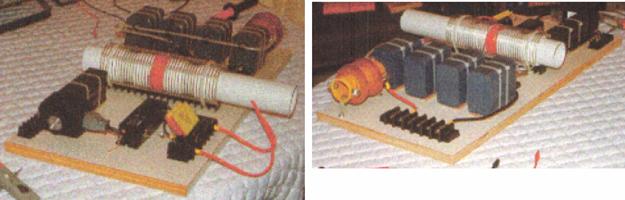

APPARATUS FOR PRODUCING AN ELECTRIC CURRENT

This patent shows the details of a lightweight device which can produce electricity using a self-powered electromagnet and chemical salts. The working life of the device before needing a recharge is estimated at some seventy years. The operation is controlled by a transmitter which bombards the chemical sample with 300 MHz radio waves. This produces radioactive emissions from the chemical mixture for a period of one hour maximum, so the transmitter needs to be run for fifteen to thirty seconds once every hour. The chemical mixture is shielded by a lead screen to prevent harmful radiation reaching the user. The output from the tiny device described is estimated to be some 10 amps at 100 to 110 volts DC.

DESCRIPTION

This invention relates to a new apparatus for producing electric current the apparatus being in the form of a completely novel secondary battery. The object of this invention is to provide apparatus of the above kind which is considerably lighter in weight than, and has an infinitely greater life than a known battery or similar characteristics and which can be re-activated as and when required in a minimum of time.

According to the present invention we provide apparatus comprising a generator unit which includes a magnet, a means for suspending a chemical mixture in the magnetic field, the mixture being composed of elements whose nuclei becomes unstable as a result of bombardment by short waves so that the elements become radio-active and release electrical energy, the mixture being mounted between, and in contact with, a pair of different metals such as copper and zinc, a capacitor mounted between those metals, a terminal electrically connected to each of the metals, means for conveying the waves to the mixture and a lead shield surrounding the mixture to prevent harmful radiation from the mixture.

The mixture is preferably composed of the elements Cadmium, Phosphorus and Cobalt having Atomic Weights of 112, 31 and 59 respectively. The mixture, which may be of powdered form, is mounted in a tube of non-conducting, high heat resistivity material and is compressed between granulated zinc at one end of the tube and granulated copper at the other end, the ends of the tube being closed by brass caps and the tube being carried in a suitable cradle so that it is located between the poles of the magnet. The magnet is preferably an electro-magnet and is energised by the current produced by the unit.

The means for conveying the waves to the mixture may be a pair of antennae which are exactly similar to the antennae of the transmitter unit for producing the waves, each antenna projecting from and being secured to the brass cap at each end of the tube.

The transmitter unit which is used for activating the generator unit may be of any conventional type operating on ultra-shortwave and is preferably crystal controlled at the desired frequency.

DESCRIPTION OF THE DRAWINGS

Fig.1 is a side elevation of one form of the apparatus.

Fig.2 is a view is an end elevation

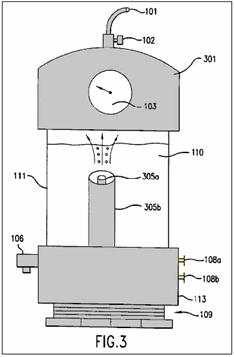

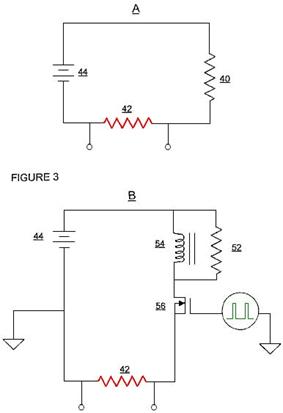

Fig.3 is a schematic circuit diagram.

In the form of our invention illustrated, the generator unit comprises a base 10 upon which the various components are mounted. This base 10, having projecting upwards from it a pair of arms 11, which form a cradle housing 12 for a quartz tube 13, the cradle 12 preferably being made of spring material so that the tube 13 is firmly, yet removably held in position. The arms 11 are positioned relative to the poles 14 of an electromagnet 15 so that the tube 13 is located immediately between the poles of the magnet so as to be in the strongest magnetic field created by the electromagnet. The magnet serves to control the alpha and beta rays emitted by the cartridge when it is in operation.

The ends of the quartz tube 13 are each provided with a brass cap 16, and these caps 16 are adapted to engage within the spring cradles 12 and the coils 17 associated with the magnet being so arranged that if the base 10 of the unit is in a horizontal plane, the poles 14 of the magnet are in a substantially vertical plane.

Also connected across the cradles is a lead capacitor 18 which may conveniently be housed in the base 10 of the unit and connected in parallel with this capacitor 18 is a suitable high frequency inductance coil 19. The unit is provided with a lead shield 20 so as to prevent harmful radiation from the quartz tube as will be described later.

The quartz tube 13 has mounted in it, at one end, a quantity of granulated copper which is in electrical contact with the brass cap 16 at that end of the tube. Also mounted within the tube and in contact with the granulated copper is a chemical mixture which is in powdered form and which is capable of releasing electrical energy and which becomes radioactive when subjected to bombardment by ultra-short radio waves.

Mounted in the other end of the tube, and in contact with the other end of the powdered chemical mixture is a quantity of granulated zinc which is itself in contact with the brass cap on this end of the tube, the arrangement being that the chemical mixture is compressed between the granulated copper and the granulated zinc.

Projecting outwards from each brass cap 16, and electrically connected to them, is an antenna 21. Each antenna 21 corresponding exactly in dimension, shape and electrical characteristics to the antenna associated with a transmitter unit which is to produce the ultra shortwaves mentioned earlier.

The electromagnet 15 is conveniently carried by a centrally positioned pillar 22 which is secured to the base 10. At the upper end of pillar 22 there is a cross-bar 23, which has the high frequency coil 19 attached to one end of it. The other end of the cross-bar 23 is bent around into the curved shape as shown at 24 and is adapted to bear against a curved portion 25 of the base 26 of the electromagnet 15. A suitable locking device is provided for holding the curved portions 24 and 25 in the desired angular position, so that the position of the poles 14 of the electromagnet can be adjusted about the axis of the quartz tube 13.

The transmitter unit is of any suitable conventional type for producing ultra shortwaves and may be crystal controlled to ensure that it operates at the desired frequency with the necessity of tuning. If the transmitter is only required to operate over a short range, it may conveniently be battery powered but if it is to operate over a greater range, then it may be operated from a suitable electrical supply such as the mains. If the transmitter is to be tuned, then the tuning may be operated by a dial provided with a micrometer vernier scale so that the necessary tuning accuracy may be achieved.

The mixture which is contained within the quartz tube is composed of the elements Cadmium, Phosphorus and Cobalt, having atomic weights 112, 31 and 59 respectively. Conveniently, these elements may be present in the following compounds, and where the tube is to contain thirty milligrams of the mixture, the compounds and their proportions by weight are:

1 Part of Co (No3) 2 6H2O

2 Parts of

CdCl2

3 Parts of 3Ca (Po3) 2 + 10C.

The cartridge which consists of the tube 13 with the chemical mixture in it is preferably composed of a number of small cells built up in series. In other words, considering the cartridge from one end to the other, at one end and in contact with the brass cap, there would be a layer of powdered copper, then a layer of the chemical mixture, then a layer of powdered zinc, a layer of powdered copper, etc. with a layer of powdered zinc in contact with the brass cap at the other end of the cartridge. With a cartridge some forty five millimetres long and five millimetres diameter, some fourteen cells may be included.

The cradles 12 in which the brass caps 16 engage, may themselves form terminals from which the output of the unit may be taken. Alternatively, a pair of terminals 27 may be connected across the cradles 12, these terminals 27 being themselves provided with suitable antennae 28, which correspond exactly in dimensions, shape and electrical characteristics to the antennae associated with the transmitter, these antennae 28, replacing the antennae 21.

In operation with the quartz tube containing the above mixture located between the granulated copper and the granulated zinc and with the tube itself in position between the poles of the magnet, the transmitter is switched on and the ultra shortwaves coming from it are received by the antennae mounted at each end of the tube and in contact with the copper and zinc respectively, the waves being thus passed through the copper and zinc and through the mixture so that the mixture is bombarded by the short waves and the Cadmium, Phosphorus and Cobalt associated with the mixture become radioactive and release electrical energy which is transmitted to the granulated copper and granulated zinc, causing a current to flow between them in a similar manner to the current flow produced by a thermo couple. It has been established that with a mixture having the above composition, the optimum release of energy is obtained when the transmitter is operating at a frequency of 300 MHz.

The provision of a quartz tube is necessary for the mixture evolves a considerable amount of heat while it is reacting to the bombardment of the short waves. It is found that the tube will only last for one hour and that the tube will become discharged after an hours operation, that is to say, the radioactiveness of the tube will only last for one hour and it is therefore necessary, if the unit is to be run continuously, for the transmitter to be operated for a period of some fifteen to thirty seconds duration once every hour.

With a quartz tube having an overall length of some forty five millimetres and an inside diameter of five millimetres and containing thirty milligrams of the chemical mixture, the estimated energy which will be given off from the tube for a discharge of one hour, is 10 amps at between 100 and 110 volts. To enable the tube to give off this discharge, it is only necessary to operate the transmitter at the desired frequency for a period of some fifteen to thirty seconds duration.

The current which is given off by the tube during its discharge is in the form of direct current. During the discharge from the tube, harmful radiations are emitted in the form of gamma rays, alpha rays and beta rays and it is therefore necessary to mount the unit within a lead shield to prevent the harmful radiations from affecting personnel and objects in the vicinity of the unit. The alpha and beta rays which are emitted from the cartridge when it is in operation are controlled by the magnet.

When the unit is connected up to some apparatus which is to be powered by it, it is necessary to provide suitable fuses to guard against the cartridge being short-circuited which could cause the cartridge to explode.

The estimated weight of such a unit including the necessary shielding, per kilowatt hour output, is approximately 25% of any known standard type of accumulator which is in use today and it is estimated that the life of the chemical mixture is probably in the region of seventy to eighty years when under constant use.

It will thus be seen that we have provided a novel form of apparatus for producing an electric current, which is considerably lighter than the standard type of accumulator at present known, and which has an infinitely greater life than the standard type of accumulator, and which can be recharged or reactivated as and when desired and from a remote position depending on the power output of the transmitter. Such form of battery has many applications.

JONG-SOK AN: NO-LOAD GENERATOR

Patent US 6,208,061

27th March 2001

Inventor: Jong-Sok An

NO-LOAD GENERATOR

Electrical power is frequently generated by spinning the shaft of a generator which has some arrangement of coils and magnets contained within it. The problem is that when current is drawn from the take-off coils of a typical generator, it becomes much more difficult to spin the generator shaft. The cunning design shown in this patent overcomes this problem with a simple design in which the effort required to turn the shaft is not altered by the current drawn from the generator.

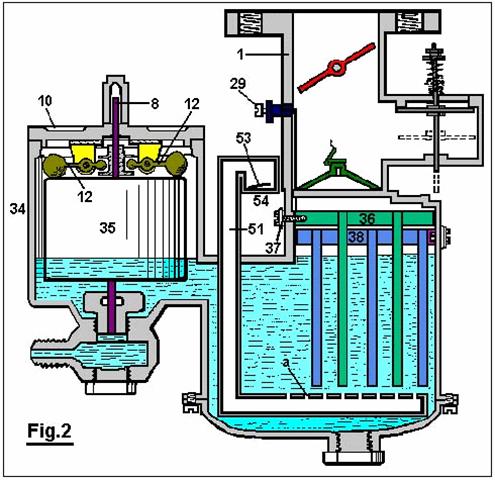

ABSTRACT

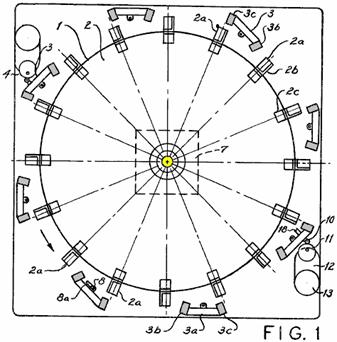

A generator of the present invention is formed of ring permanent magnet trains 2 and 2' attached and fixed on to two orbits 1 and 1' about a rotational axis 3, magnetic induction primary cores 4 and 4' attached and fixed above outer peripheral surfaces of the ring permanent magnet trains 2 and 2' at a predetermined distance from the outer peripheral surfaces, magnetic induction secondary cores 5 and 5' attached and fixed on to the magnetic induction primary cores 4 and 4' and each having two coupling, holes 6 and 6' formed therein, tertiary cores 8 and 8' inserted for coupling respectively into two coupling holes 6 and 6' of each of the associated magnetic induction secondary cores 5 and 5' opposite to each other, and responsive coils 7 and 7'. The ring permanent magnetic trains 2 and 2' are formed of 8 sets of magnets with alternating N and S poles, and magnets associated with each other in the axial direction have opposite polarities respectively and form a pair.

DESCRIPTION

TECHNICAL FIELD

The present invention relates to generators, and particularly to a load-free generator which can maximise the generator efficiency by erasing or eliminating the secondary repulsive load exerted on the rotor during electric power generation.

BACKGROUND ART

The generator is a machine which converts mechanical energy obtained from sources of various types of energy such as physical, chemical or nuclear power energy, for example, into electric energy. Generators based on linear motion have recently been developed while most generators are structured as rotational type generators. Generation of electromotive force by electromagnetic induction is a common principle to generators regardless of their size or whether the generator is AC or DC generator.

The generator requires a strong magnet such as permanent magnet and electromagnet for generating magnetic field as well as a conductor for generating the electromotive force, and the generator is structured to enable one of them to rotate relative to the other. Depending on which of the magnet and the conductor rotates, generators can be classified into rotating-field type generators in which the magnetic field rotates and rotating-armature type generators in which the conductor rotates.

Although the permanent magnet can be used for generating the magnetic field, the electromagnet is generally employed which is formed of a magnetic field coil wound around a core to allow direct current to flow through them. Even if a strong magnet is used to enhance the rotational speed, usually the electromotive force produced from one conductor is not so great. Thus, in a generally employed system, a large number of conductors are provided in the generator and the electromotive forces generated from respective conductare serially added up so as to achieve a high electric power.

As discussed above, a usual generator produces electricity by mechanically rotating a magnet (or permanent magnet) or a conductor (electromagnet, electrically responsive coil and the like) while reverse current generated at this time by magnetic induction (electromagnetic induction) and flowing through the coil causes magnetic force which pulls the rotor so that the rotor itself is subjected to unnecessary load which reaches at least twice the electric power production.

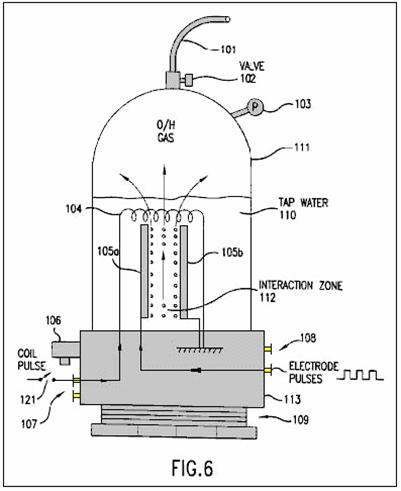

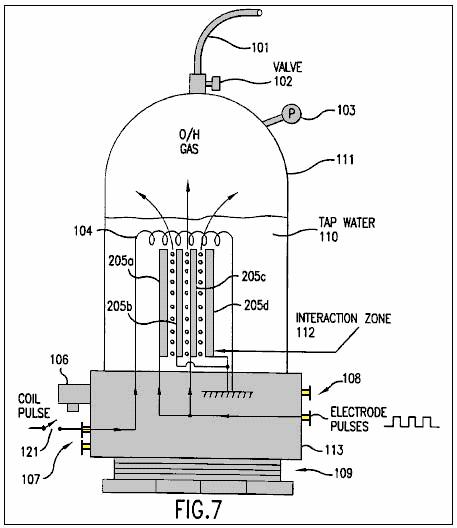

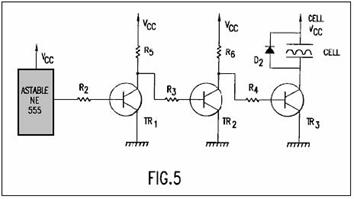

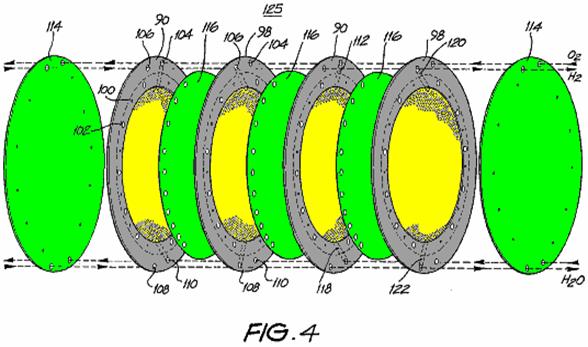

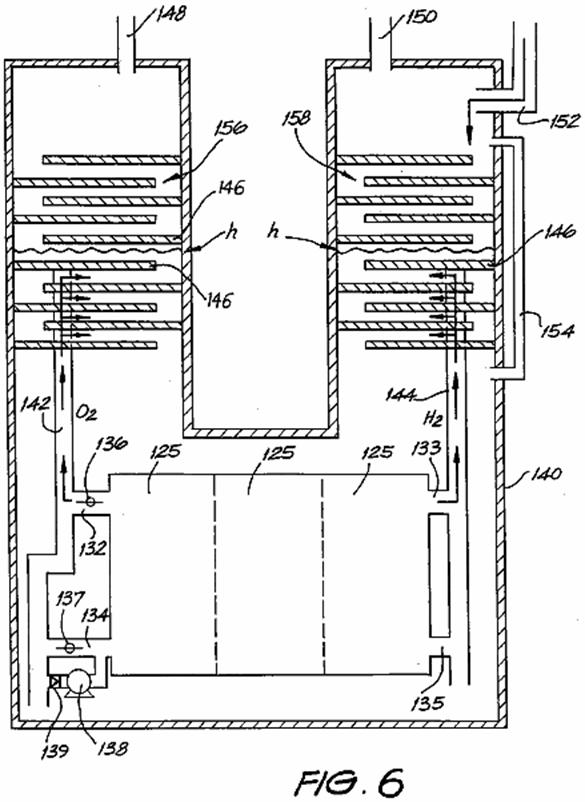

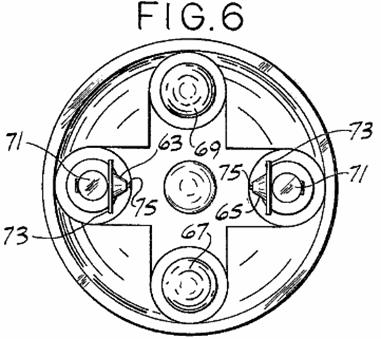

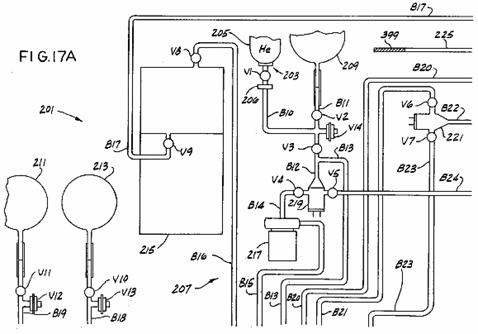

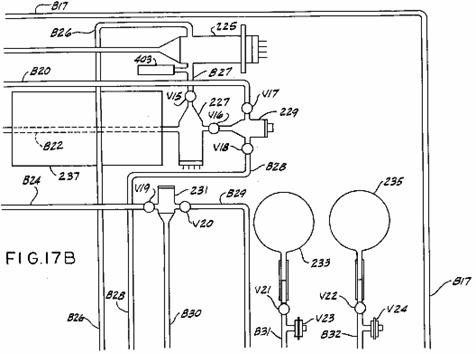

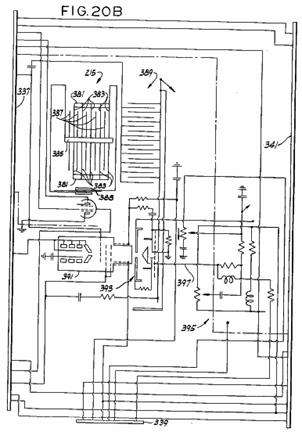

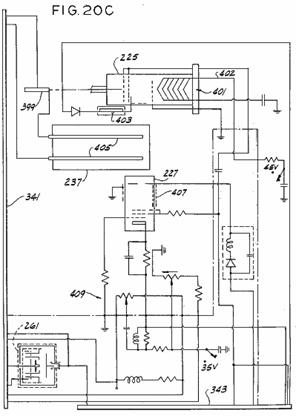

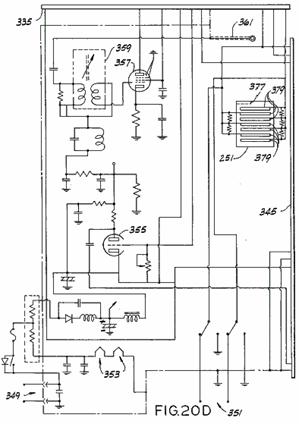

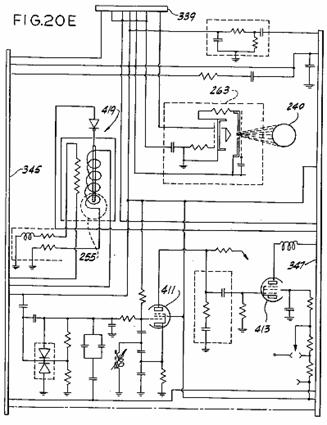

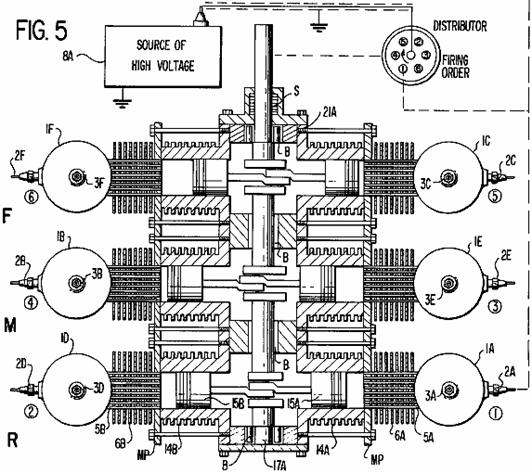

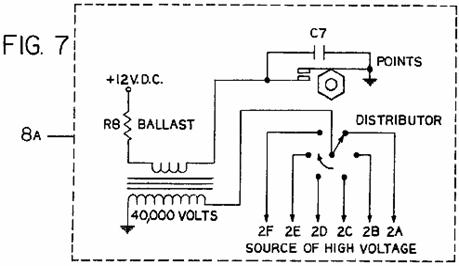

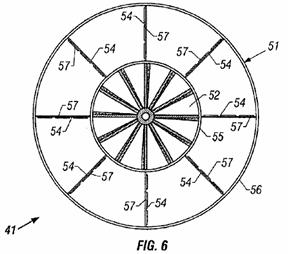

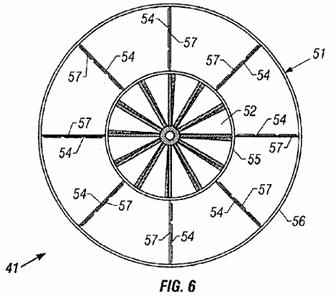

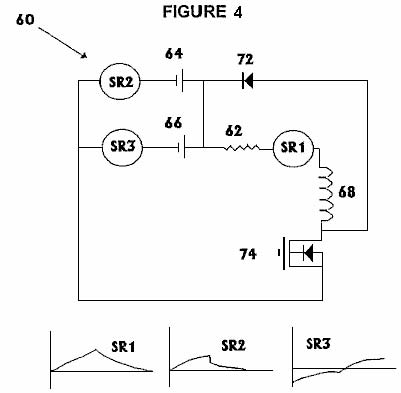

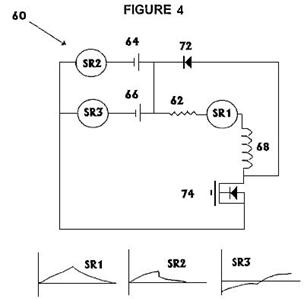

Fig.6 illustrates that the load as discussed above is exerted on a rotor in a rotating-field type generator mentioned above.

Referring to Fig.6, a permanent magnet train 104 is arranged about an axis of rotation 106 such that N poles and S poles are alternately located on the outer peripheral surface of the train. At a certain distance outward from the outer periphery of permanent magnet train 104, a magnetic induction core 100 is arranged and a coil 102 is wound around magnetic induction core 100.

As permanent magnet train 104 rotates, the magnetic field produced in the coil by permanent magnet train 104 changes to cause induced current to flow through coil 102. This induced current allows coil 102 to generate a magnetic field 110 which causes a repulsive force exerted on permanent magnet train 104 in the direction which interferes the rotation of the magnet train.

For example, in the example shown in Fig.6, the S pole of magnetic field 110 faces permanent magnet train 104. The S pole of permanent magnet train 104 approaches coil 102 because of rotation of permanent magnet train 104, resulting in the repulsive force as described above.

If reverse current flows in a responsive coil of an armature wound around a magnetic induction core of a generator so that the resulting load hinders the rotor from rotating, reverse magnetic field of the armature responsive coil becomes stronger in proportion to the electricity output and accordingly a load corresponding to at least twice the instantaneous consumption could occur.

If electric power of 100W is used, for example, reverse magnetic field of at least 200W is generated so that an enormous amount of load affects the rotor to interfere the rotation of the rotor.

All of the conventional generators are subjected to not only a mechanical primary load, i.e. the load when the electric power is not consumed but a secondary load due to reverse current which is proportional to electric power consumption and consequently subjected to a load of at least twice the instantaneous consumption.

Such an amount of the load is a main factor of reduction of the electric power production efficiency, and solution of the problem above has been needed.

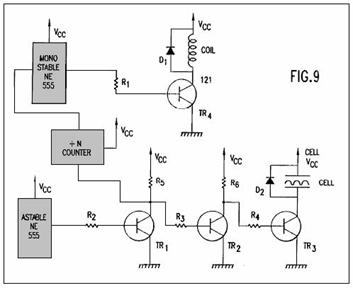

DISCLOSURE

OF THE INVENTION

One object of the present invention is to provide a generator capable of generating electric power with high efficiency by cancelling out the secondary load except the mechanical load of the generator, i.e. cancelling out the load which is generated due to reverse current of a responsive coil of an armature wound around a magnetic induction core, so as to entirely prevent the secondary load from being exerted.

In short, the present invention is applied to a load-free generator including a rotational axis, a first ring magnet train, a second ring magnet train, a first plurality of first magnetic induction primary cores, a first plurality of second magnetic induction primary cores, a first responsive coil, and a second responsive coil.

The first ring magnet train has N poles and S poles successively arranged on an outer periphery of a first rotational orbit about the rotational axis. The second ring magnet train has magnets successively arranged on an outer periphery of a second rotational orbit about the rotational axis at a predetermined distance from the first rotational orbit such that the polarities of the magnets on the second rotational orbit are opposite to the polarities at opposite locations on the first rotational orbit respectively. The first plurality of first magnetic induction primary cores are fixed along a first peripheral surface of the first ring magnet train at a predetermined distance from the first peripheral surface. The first plurality of second magnetic induction primary cores are fixed along a second peripheral surface of the second ring magnet train at a predetermined distance from the second peripheral surface. A first plurality of first coupling magnetic induction cores and a first plurality of second coupling magnetic induction cores are provided in pairs to form a closed magnetic circuit between the first and second magnetic induction primary cores opposite to each other in the direction of the rotational axis. The first responsive coil is wound around the first coupling magnetic induction core. The second responsive coil is wound around the second coupling magnetic induction core, the direction of winding of the second responsive coil being reversed relative to the first responsive coil.

Preferably, in the load-free generator of the invention, the first ring magnet train includes a permanent magnet train arranged along the outer periphery of the first rotational orbit, and the second ring magnet train includes a permanent magnet train arranged along the outer periphery of the second rotational orbit.

Still preferably, the load-free generator of the present invention further includes a first plurality of first magnetic induction secondary cores provided on respective outer peripheries of the first magnetic induction primary cores and each having first and second coupling holes, and a first plurality of second magnetic induction secondary cores provided on respective outer peripheries of the second magnetic induction primary cores and each having third and fourth coupling holes. The first coupling magnetic induction cores are inserted into the first and third coupling holes to couple the first and second magnetic induction secondary cores, and the second coupling magnetic induction cores are inserted into the second and fourth coupling holes to couple the first and second magnetic induction secondary cores.

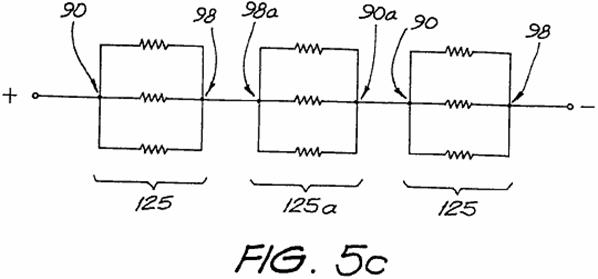

Alternatively, the load-free generator of the present invention preferably has a first plurality of first responsive coils arranged in the rotational direction about the rotational aids that are connected zigzag to each other and a first plurality of second responsive coils arranged in the rotational direction about the rotational axis that are connected zigzag to each other.

Alternatively, in the load-free generator of the present invention, preferably the first plurality is equal to 8, and the 8 first responsive coils arranged in the rotational direction about the rotational axis are connected zigzag to each other, and the 8 second responsive coils arranged in the rotational direction about the rotational axis are connected zigzag to each other.

Accordingly, a main advantage of the present invention is that two responsive coils wound respectively in opposite directions around a paired iron cores are connected to cancel reverse magnetic forces generated by reverse currents (induced currents) flowing through the two responsive coils, so that the secondary load which interferes the rotation of the rotor is totally prevented and thus a load-free generator can be provided which is subjected to just a load which is equal to or less than mechanical load when electric power production is not done, i.e. the rotational load even when the generator is operated to the maximum.

Another advantage of the present invention is that the reverse magnetic force, as found in the conventional generators, due to reverse current occurring when the rotor rotates is not generated, and accordingly load of energy except the primary gravity of the rotor and dynamic energy of the rotor is eliminated to increase the amount of electricity output relative to the conventional electric power generation system and thus enhance the electric power production and economic efficiency.

BRIEF DESCRIPTION OF THE DRAWINGS

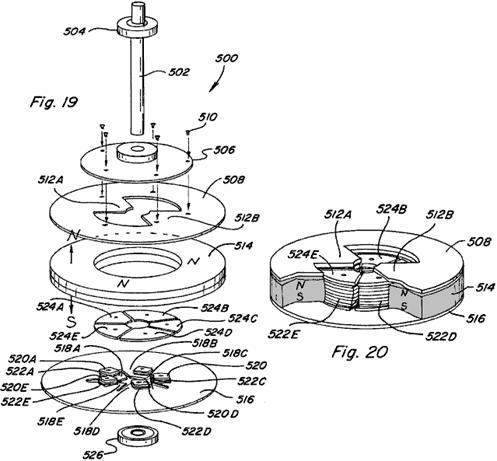

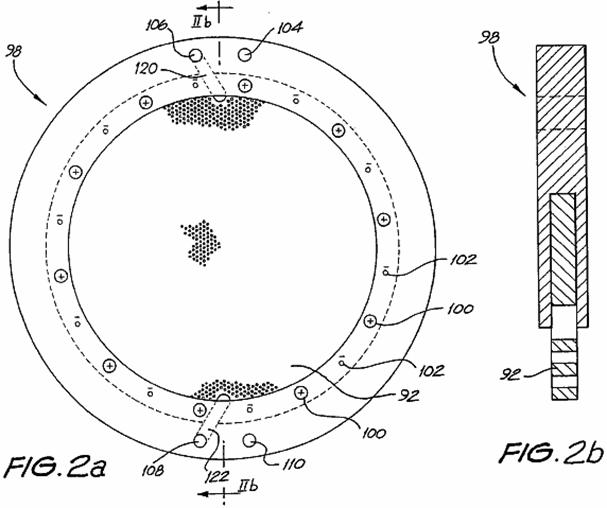

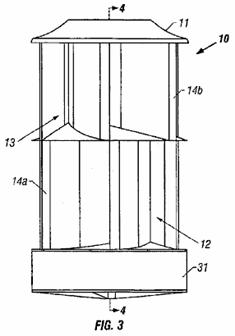

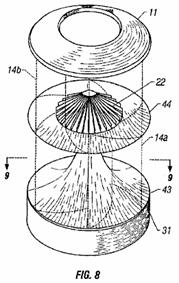

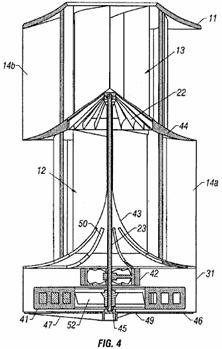

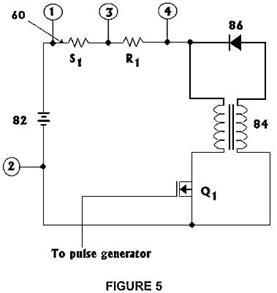

Fig.1 is a cross sectional view of a rotating-field type generator according to an embodiment of the present invention illustrating an arrangement a permanent magnet, magnetic induction cores and coils.

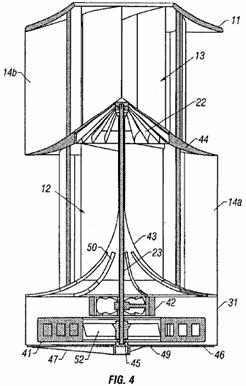

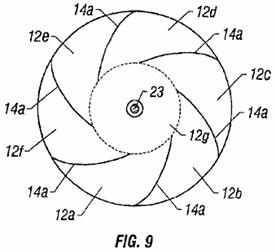

Fig.2 is a partial schematic view illustrating a magnetic array of the permanent magnet rotor and an arrangement of one of magnetically responsive coils placed around that rotor in an embodiment of the present invention.

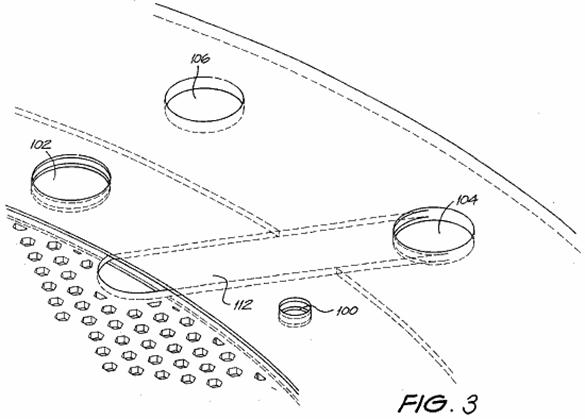

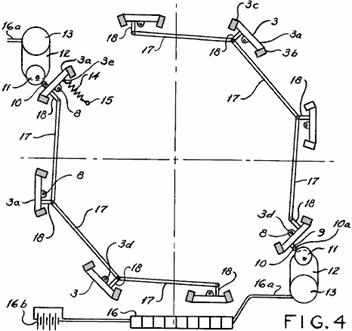

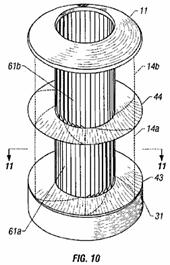

Fig.3 illustrates a structure of the magnetically responsive coils and cores in the embodiment of the present invention.

Fig.4 is an enlarged plan view of magnetically sensitive cores and coil portions of the load-free generator of the present invention illustrating magnetic flow therethrough.

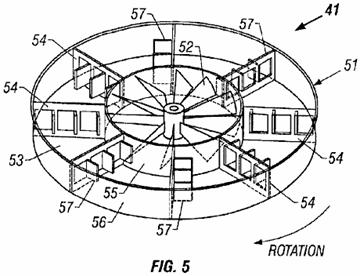

Fig.5 is an exploded view about a central axis showing the interconnection of magnetic field coils which are respectively wound around tertiary cores surrounding the permanent magnet rotor in FIG. 1 according to the present invention.

Fig.6 illustrates generation of the secondary load in a conventional generator.

BEST MODES FOR CARRYING OUT THE INVENTION

The structure and operation of a load-free generator according to the present invention are now described in conjunction with the drawings.

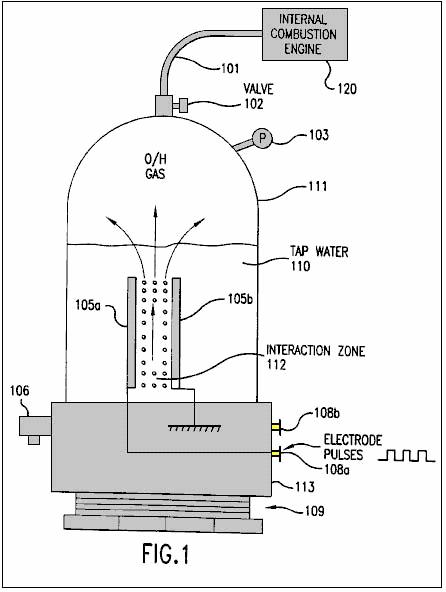

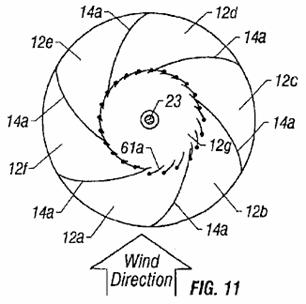

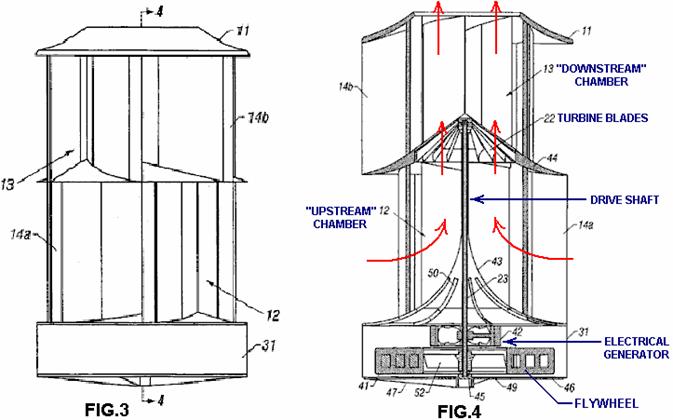

Fig.1 illustrates a cross sectional structure of the load-free generator of the invention perpendicular to a rotational axis 3.

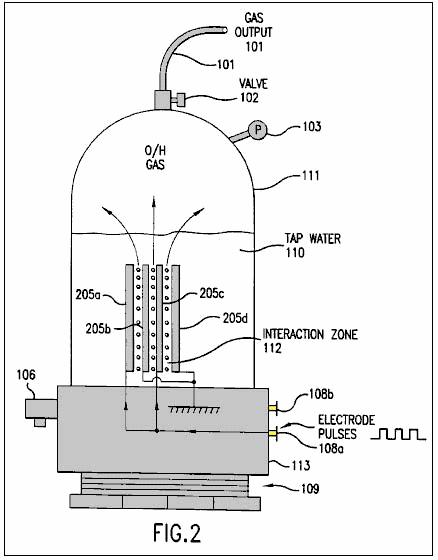

Fig.2 partially illustrates a cross sectional structure of the load-free generator of the invention in parallel to rotational axis 3. Specifically, in Fig.2, only one of eight sets of magnetic induction primary cores 4 and 4' arranged around rotational axis 3 as described below is representatively shown.

Referring to Fig.1 and Fig.2, the structure of the load-free generator of the invention is now described. Permanent magnet trains 2 and 2' in ring forms are attached and fixed to respective left and right orbits 1 and 1' provided relative to rotational axis 3 with a certain interval between them. Permanent magnet trains 2 and 2' are fixed onto left and right orbits 1 and 1' respectively such that the polarities on the outer peripheral surface of each magnet train relative to the rotational axis are alternately N poles and S poles. The permanent magnet trains are rotatable about the axis. Further, the facing polarities of respective permanent magnet train 2 and permanent magnet train 2' relative to the direction of rotational axis 3 are arranged to be opposite.

As shown in Fig.2, rotational axis 3 and a case 9 are joined by a bearing 10 at a certain distance from the permanent magnet trains 2 and 2'.

At a predetermined distance from permanent magnet trains 2 and 2', magnetic induction primary cores 4 and 4' with respective coils wound around them are fixed to case 9.

In addition, magnetic induction secondary cores 5 and 5' each having two coupling holes 6 and 6' formed therein are structured by stacking and coupling a plurality of thin cores attached and fixed to magnetic induction primary cores 4 and 4' respectively and the secondary cores are attached and fixed to case 9.

Magnetic induction tertiary cores 8 and 8' are inserted respectively into coupling holes 6 and 6' of magnetic induction secondary cores 5 and 5' so as to couple magnetic induction secondary cores 5 and 5' of each other.

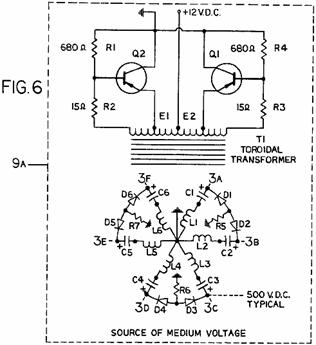

Responsive coils 7 and 7' are wound in opposite directions to each other around respective magnetic induction cores 8 and 8'.

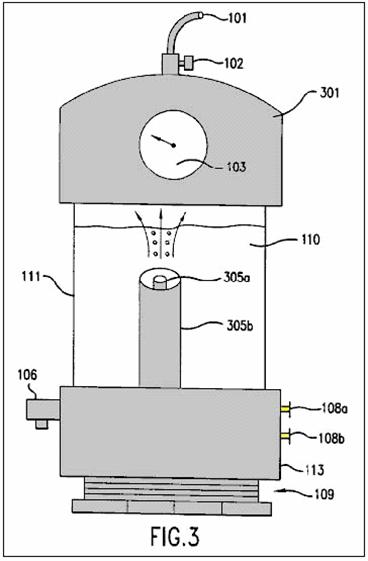

Fig.3 illustrates a structure formed of magnetic induction secondary cores 5 and 5', magnetic induction cores 8 and 8' and responsive coils 7 and 7' viewed in the direction perpendicular to rotational axis 3.

As explained above, the directions of windings of responsive coils 7 and 7' are respectively opposite to each other around magnetic induction cores 8 and 8' which couple magnetic induction secondary cores 5 and 5'.

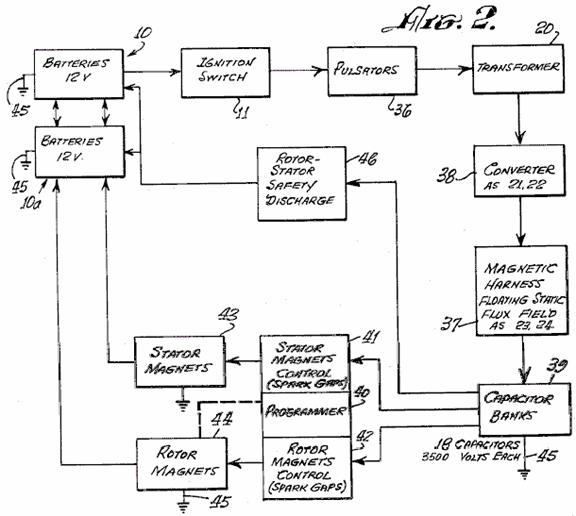

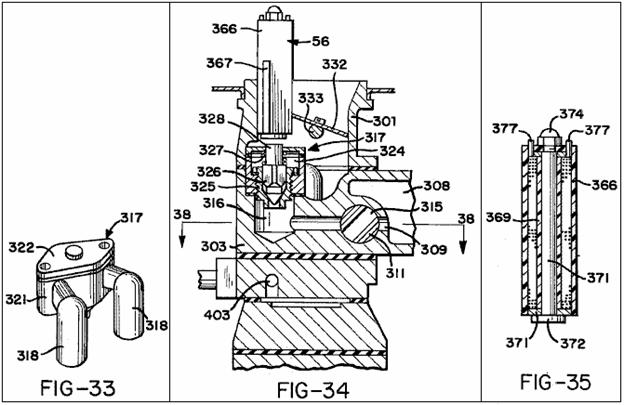

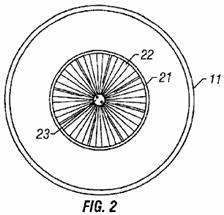

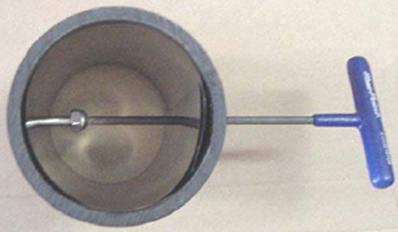

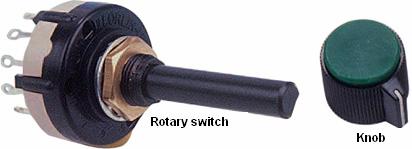

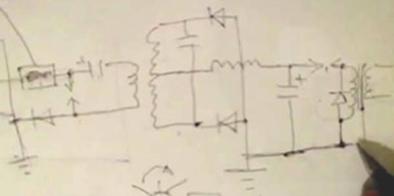

In the structure described in conjunction with Fig.1, Fig.2 and Fig.3, when rotational axis 3 of the generator rotates, permanent magnetic trains 2 and 2' accordingly rotate to generate magnetically sensitive currents (electromagnetically induced current) in responsive coils 7 and 7' and the current thus produced can be drawn out for use.